Position Sensor Technology Comparison

for Hydraulic Cylinder Feedback

Edward E. Herceg

Chief Technology Officer

Alliance Sensors Group a div. of H.G. Schaevitz LLC

Position

feedback sensors for hydraulic or pneumatic cylinders have used

one of three traditional technologies: Magnetostrictive,

Variable Resistance, and Variable Inductance sensors. While

other sensor technologies have occasionally been used

successfully in this application, the focus of this article is

the comparison among these three most popularly used

technologies. As the demand for increased control and

functionality has increased over the years, sensor- instrumented

cylinders are becoming more important in the heavy industry,

subsea, and mobile equipment worlds. Ultimately, a user or

systems integrator must determine the requirements of the

application and which technology best satisfies it on a total

installed cost versus performance basis. The strengths and

weaknesses of magnetostrictive, variable resistance, and

variable inductance sensors are discussed below, along with a

chart for feature-by-feature comparisons. Position

feedback sensors for hydraulic or pneumatic cylinders have used

one of three traditional technologies: Magnetostrictive,

Variable Resistance, and Variable Inductance sensors. While

other sensor technologies have occasionally been used

successfully in this application, the focus of this article is

the comparison among these three most popularly used

technologies. As the demand for increased control and

functionality has increased over the years, sensor- instrumented

cylinders are becoming more important in the heavy industry,

subsea, and mobile equipment worlds. Ultimately, a user or

systems integrator must determine the requirements of the

application and which technology best satisfies it on a total

installed cost versus performance basis. The strengths and

weaknesses of magnetostrictive, variable resistance, and

variable inductance sensors are discussed below, along with a

chart for feature-by-feature comparisons.

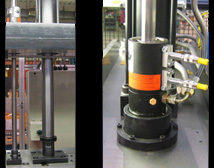

Initially, a point to be noted is that all of these common

sensing technologies utilize a long probe that extends into a

deep, small diameter blind hole which has been gun-drilled into

the internal end of the cylinder rod.

Magnetostrictive technology has been the preferred technology

for high accuracy applications. The sensor, often called an LDT

or MLDT, incorporates a stainless steel tubular probe and a

short toroidal permanent magnet assembly around it that is

installed in a counterbore in the piston. The most common

package is designed to thread the sensors' electronics housing

into an o-ring port in the back of a cylinder, with the long

slender probe inserted into the rod's bore. It uses the “time of

flight" principle to determine the magnet's position with high

accuracy and moderate response time. The magnet is used to

reflect a torsional mechanical pulse which is transmitted along

a special wire inside of the probe called a waveguide.

Typically, each of the magnetostrictive sensor manufacturers has

its own style of magnet with unique mounting features like the

number of holes, the hole pattern, etc. Magnetostrictive sensors

can consume a fair amount of power and are not the most

mechanically rugged sensors. They offer electrical performance

over mechanical robustness, because they are subject to shock

and vibration issues. Yet, while there are some potential

drawbacks mechanically, the magnetostrictive sensor's package

design is tailor-made for port-mounted in-cylinder use.

Variable Resistance potentiometer-type sensors, commonly called

pots, are selected where purchase cost is a driver and high

accuracy is not paramount. A resistance pot is usually embedded

into the cylinder's rear end plate, as opposed to the port

mounting of magnetostrictive sensors. It uses an insulated round

carrier which is attached to the internal end of the gun-drilled

cylinder rod and supports an electrically conductive wiper that

contacts the surface of a partially conductive plastic probe. As

the wiper moves along this plastic element, its resistance

changes in a linear fashion, making it fairly easy to determine

the carrier's position and, thus, the rod's position. Pots have

been seen as a good position measurement solution for use in

cylinders because of their ruggedness, favorable

stroke-to-length ratio, and their large analog DC voltage

output, which is a big percentage of the input voltage. The

major drawback to resistance pots is wearout, especially if the

cylinder is actuated at a high frequency, or even more

importantly, dithered over a short range to improve a system's

dynamic characteristics. Since a resistance pot is embedded into

the cylinder, replacement of a worn out pot can be very time

consuming and expensive, and could even result in the need for a

completely new cylinder.

Variable inductance position sensors have been used in the

cylinder industry but have not had the widespread recognition of

magnetostrictive sensors or resistance potentiometers. This

non-contacting technology has many significant advantages over

resistance potentiometers regarding product life and long-term

reliability, and usually can compete favorably with the

performance of magnetostrictive sensors in terms of linearity,

resolution, and frequency response, but at a significantly lower

cost. Equally important is the fact that variable inductance

sensors can withstand much greater shocks and vibration, such as

those commonly found in heavy industrial and mobile equipment

applications.

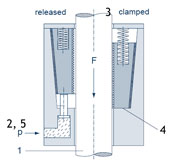

Linear variable inductance sensors cover the middle ground

between the higher level of performance and external port

mounting flexibility associated with a magnetostrictive sensor

and the ruggedness and price of an embedded resistance

potentiometer. These sensors operate by measuring the resonant

frequency of an oscillator circuit that uses an inductive probe

whose inductance is varied by the position of the gun-drilled

rod over it. Typically offered in full scale ranges of 4 inches

(100 mm) to 36 inches (900 mm), both port-mounted and embedded

packages are available, with connector and cable terminations

that match those found on most catalog magnetostrictive sensors.

These sensors offer either an analog DC voltage or current

output, with an SSI digital output available for OEM

applications. The variable inductance sensor presents a

non-contacting solution that does not require a ring magnet. In

fact, if a variable inductance sensor were installed to replace

an existing magnetostrictive sensor, the magnet can be left in

place in the cylinder rod end without interfering with the

sensor’s basic operation.

In the past few years, the requirements for instrumented

cylinders for subsea applications have dramatically increased.

Variable inductance sensors can be offered in a pressure-sealed

version that allows a user to install the sensor/cylinder in a

subsea environment in depths of 10,000 feet (3000 m) with 3000

psig of internal hydraulic pressure.

Remote field calibration is a standard feature offered on many

variable inductance sensors. This feature permits a user to

scale the output of the sensor while it is being installed on

the cylinder. With a simple push of a button to set the zero and

the full scale output points, the sensor will give the desired

full scale output over its newly set range, so it is no longer

necessary to scale the unit in an operating control system.

In another fluid power application, though not commonly used

inside of hydraulic cylinders, LVDTs are often used in spool

position feedback applications for two-stage hydraulic valves. A

short range variable inductance sensor with its simple inductive

probe inserted into a hole in the end of the main spool is very

often an easier installation than an LVDT that requires an

isolation tube to seal off the its core from the valve’s pilot

pressure.

Where there are still many fluid power applications where

resistance potentiometers and magnetostrictive sensors are a

good solution, these applications tend to fall to either side of

a bell curve. Recent electronic advancements and the flexibility

of package designs make variable inductance sensors very cost

effective for mainstream in-cylinder applications that tend to

be near the peak of that bell curve.

Alliance Sensors Group

102 Commerce Dr

Unit 8

Moorestown, NJ 08057

Ph # 856-727-0250

www.alliancesensors.com

|

IFPE & CONEXPO-CON/AGG 2014 attract

nearly 130,000, set new exhibit & education records

The

future on display as global industry showcase spotlights new

product innovations, technology The

future on display as global industry showcase spotlights new

product innovations, technology

IFPE and CONEXPO-CON/AGG 2014 took center stage in Las Vegas

March 4-8 with tremendous energy and serious buyers. Total

registration of 129,364 soared past the last edition of the

shows as they achieved the second-highest attendance in their

history. The shows also set new records for exhibit space,

number of exhibitors and education tickets sold.

The co-located IFPE and CONEXPO-CON/AGG, at the Las Vegas (USA)

Convention Center, delivered a global showcase of the newest

product innovations and technologies for the construction,

construction materials and fluid power/power transmission/motion

control industries with more than 1,000 new products and

services on display.

Attendees also took advantage of the shows’ strong industry

education programs and the unparalleled opportunity to connect

with industry peers, take the pulse of what’s happening and

learn what the future holds.

“The enthusiasm and traffic on the show floor was just

incredible. Exhibitors cited the high quality of attendees; they

told us these were serious buyers and reported robust sales to

existing as well as new customers that exceeded their

expectations,” stated Megan Tanel, CONEXPO-CONAGG show director.

Quality Attendance, International Scope

IFPE & CONEXPO-CON/AGG 2014 maintained the growing international

scope of the shows with international registrations totaling

more than 31,000, or an increase of nine percent from the most

recent events. The number of countries represented increased to

170 from 159 in 2011, and the number of international attendees

matched the record 24 percent of total attendance set in 2011.

International attendance drew heavily from Latin America, China,

Canada, and Europe.

More than 75 percent of show visitors were in managerial roles

(with 36 percent of these with the top titles of president/owner

and vice president/general manager/chief financial officer).

Both shows set new records for exhibit space and number of

exhibitors, CONEXPO-CON/AGG with more than 2.35 million net

square feet of exhibit space and more than 2,000 exhibitors, and

IFPE with more than 161,000 net square feet and 400 exhibitors.

A record 41,000 education ticket sales were sold to the shows’

education programs, underscoring their relevance to helping

attendees succeed in today’s business environment.

“CONEXPO-CON/AGG and IFPE 2014 reflected the feeling of momentum

building in the industry. We are industry-run shows with

industry needs put first; these show numbers are a testament to

the value attendees, exhibitors, and other stakeholders derive

from their participation,” stated Melissa Magestro, IFPE show

director.

Global Industry Gathering Place

Among the show visitors were Acting U.S Deputy Secretary of

Commerce Patrick D. Gallagher, Acting U.S. Deputy Secretary of

Transportation Victor Mendez and former U.S. Rep. James

Oberstar, who served as chairman of the House Transportation and

Infrastructure Committee from 2007 to 2011.

The shows were chosen for the prestigious U.S. Department of

Commerce (DOC) International Buyer Program, which helps

facilitate global attendance. More than 50 official

international attendee delegations were organized by DOC as well

as show industry partners.

More than 95 allied associations and groups were official

supporting organizations, coming from the U.S., Canada and 16

other countries worldwide.

Several national industry associations held their annual

conventions or high-level board meetings at the shows; they

joined hundreds of other industry and company meetings, from

large events to smaller committees and other groups, all taking

advantage of the shows to meet and share knowledge and learn

from one another.

Education and Exhibits

The CONEXPO-CON/AGG 2014 education program covered 120 sessions

over 10 targeted tracks. The IFPE Technical Conference anchored

IFPE 2014 education, joined by half-day “college-level courses”

and a new Fluid Power Seminar series, from Hydraulics &

Pneumatics magazine.

CONEXPO-CON/AGG featured a new Demolition & Recycling exhibit

pavilion from the Construction & Demolition Recycling

Association (CDRA) and the Technology & Construction Solutions

pavilion from the Associated General Contractors of America.

IFPE featured exhibit pavilions from the Power Transmission

Distributors Association (PTDA) and for sensors manufacturers

and product suppliers.

Reinforcing the global scope of the shows were eight

international exhibit pavilions: CONEXPO-CON/AGG with China,

Ireland, Korea, Spain and United Kingdom, and IFPE with China,

Italy and Taiwan.

Show safety and education/training events at the shows included:

NRMCA International Truck Mixer Driver Championship, from the

National Ready Mixed Concrete Association

Lift Safety Zone, from NCCCO National Commission for the

Certification of Crane Operators and IPAF International Powered

Access Federation

Crane Operator Rodeo from Maximum Capacity Media

Industry recognition and networking events and programs also

amplified the show experience:

Innovation Awards program (from Diesel Progress magazine and

global powertrain specialist ZF Friedrichshafen)

Young Leaders event (from Construction Equipment magazine)

Quality of Life industry recognition campaign (from Dexter +

Chaney)

5K Run/Walk benefiting the non-profit Injured Marine Semper Fi

Fund (from Maximum Capacity Media)

Night at the Race Track hospitality event at the Las Vegas Motor

Speedway

Visit www.conexpoconagg.com and www.ifpe.com for the latest show

information.

To view Photos, visit online www.conexpoconagg.com or

www.ifpe.com in Media Services/Photos.

To hear what people onsite were saying about the show, visit

online at http://www.youtube.com/user/conexpoconagg -

and see these links:

http://www.youtube.com/watch?v=6YZAIRm4YEI&list=UUecbg2kv5U269fvLkNhvWGA

http://www.youtube.com/watch?v=Yx96r4FM5qE&list=UUecbg2kv5U269fvLkNhvWGA

http://www.youtube.com/watch?v=ZHbxEdmXXzU&list=UUecbg2kv5U269fvLkNhvWGA |

Solutions Come Together

IFPE

is the leading international exposition and technical conference

dedicated to the integration of fluid power with other

technologies for power transmission and motion control

applications. Held every three years, the exposition showcases

the newest innovations and expertise. IFPE

is the leading international exposition and technical conference

dedicated to the integration of fluid power with other

technologies for power transmission and motion control

applications. Held every three years, the exposition showcases

the newest innovations and expertise.

IFPE 2014 Will Feature

-Over 400 exhibitors – making this the largest IFPE!

-Product concentration areas; making it easy for visitors to

locate specific products, services and exhibitors of interest

-More than 100 cutting-edge education sessions at the IFPE

Technical conference, focusing on the newest technologies, best

practices, the latest research and developments, including:

-Keynote presentations

-College-level courses in hydraulics and pneumatics

-Thousands of industry professionals from all sectors of the

fluid power, power transmission and motion control industries.

Aerospace/Defense

Agricultural Engineering

Amusement Machinery

Automotive Mfg./Supplier

Chemical & Petroleum Processing

Construction/Mining/Logging

Distribution

Electrical Machinery

Engineering Services

Factory Automation

Fluid Power Products

|

Instruments, Controls

Machine Tools

Material Handling

Metal Processing

Off-Highway Vehicles

On-Highway Vehicles (not autos)

Plastics/Rubber Working Machinery

Power Transmission |

Co-located with CONEXPO-CON/AGG 2014, the largest

international gathering place for the construction industries

|

HAWE

Valves Assists Off-Road Motorsport Vehicles HAWE

Valves Assists Off-Road Motorsport Vehicles

CHARLOTTE, N.C.– January, 2014 – HAWE Hydraulics, a leading

global manufacturer and supplier of sophisticated hydraulic

components and controls for the mobile, industrial, and

renewable energy markets

Dakar 2014, is a legendary sporting event that challenges

drivers‘ endurance, racing skills and strategic navigational

competencies. This intense off-road race is made up of two

marathon stages that stretch across miles of South America’s

desertous terrain. Drivers take great precautions ensuring their

vehicles can withstand the wear and tear of the sand dunes and

off-road courses. For this reason HAWE Hydraulics took part in

servicing the dual hydraulically mounted jacks for the Chevy

Colorado Z71 Rally Raid prototype vehicles.

HAWE’s

reputation for long-lasting, durable products make them a

perfcect match for this project. SG 1L – AKS valves were used

for the racing vehicles. HAWE’s SG Directional Spool Valves

allow up to 400 bar, 100 lpm and serves to control the oil flow

and directional movements of the jacks. Since the valve system

is entirely made up of steel the housing unit is resistant to

pressure surges and leakages. This eliminates the chance of

hairline cracks or other damages caused by the harsh desert

conditions. HAWE’s

reputation for long-lasting, durable products make them a

perfcect match for this project. SG 1L – AKS valves were used

for the racing vehicles. HAWE’s SG Directional Spool Valves

allow up to 400 bar, 100 lpm and serves to control the oil flow

and directional movements of the jacks. Since the valve system

is entirely made up of steel the housing unit is resistant to

pressure surges and leakages. This eliminates the chance of

hairline cracks or other damages caused by the harsh desert

conditions.

About HAWE Hydraulics North America:

Sixteen years ago North America was introduced to HAWE Hydraulik

through its American subsidiary HAWE Hydraulics. Today, the

partnership brings more than 60 years of German engineering and

experience to North American mobile and industrial markets. HAWE

provides integrated services that include design, manufacture,

set-up, a distributor network, and local inventory. Based in

Charlotte, NC, HAWE Hydraulics is positioned to respond quickly

to service needs, as well as provide prototypes in a timely

manner. Headquartered in Munich Germany, HAWE Hydraulik is an

ISO 9001:2000 certified international supplier with a strong

focus on supporting rapidly developing niche markets.

|

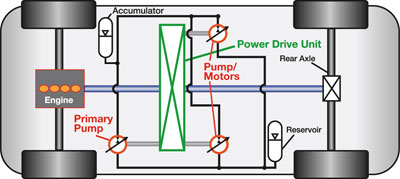

Altair

ProductDesign Unveils the World’s First Series Hydraulic Hybrid

Transit Bus Altair

ProductDesign Unveils the World’s First Series Hydraulic Hybrid

Transit Bus

BUSolutions LCO-140H to revitalize urban transit by increasing

fuel economy by 110 percent and reducing 12-year fleet

operations cost by $50 million for the average sized transit

authority

TROY, Mich. – Sept. 7, 2011 – Altair ProductDesign, a global

product development consultancy and wholly-owned subsidiary of

Altair Engineering, Inc., today unveiled the world’s first

series hydraulic hybrid transit bus. The LCO-140H (Low-Cost of

Ownership-1st 40-foot Hybrid) was developed under the

BUSolutions program in partnership with Automation Alley, in an

effort to revitalize public bus transportation in America.

Compared to the database of buses tested at Altoona, where the

Federal Transit Administration (FTA) certification program is

conducted, the LCO-140H fuel economy results are 110 percent

better than conventional diesel buses and 30 percent better than

the leading diesel-electric hybrid buses available today. The

LCO-140 achieved an industry high fuel economy of 6.9 mpg when

tested using the downtown “stop-and-go” duty cycles and test

protocol established by the FTA for transit bus certification

testing.

BUSolutions is projected to lower the cost of ownership by

$170,000 per bus as compared to a conventional diesel bus. With

the average local transit authority operating approximately 300

buses, the savings could reduce a city’s cost of transit bus

operation by approximately $50 million. When compared to an

estimated $27 million increase in operational costs for a

similar electric hybrid fleet, it is clear the LCO-140H could

revolutionize the transit industry by providing reduced fuel

consumption and emissions while improving the fiscal performance

of a regional transit authority.

BUSolutions has been a collaborative effort between public and

private entities to research, develop and commercialize advanced

transit bus systems that are significantly more fuel efficient,

have lower operating and maintenance costs, are competitively

priced and can operate without updating the infrastructure of

existing transit authorities.

In addition to investments by Altair and Automation Alley,

BUSolutions has been funded by multiple federal and state

programs including the FTA and the Michigan Economic Development

Corporation (MEDC). It also has received exceptional local

support by southeast Michigan congressional members,

transportation industry partners, and local transit authorities

SMART and the Detroit Department of Transportation (DDOT).

“This project has been a collaborative effort from start to

finish throughout the development, design and test phases. We

would not have exceeded the goals we had set for ourselves had

we not applied our knowledge and unique technologies to produce

this revolutionary bus,” said Mike Heskitt, chief operating

officer at Altair ProductDesign. “BUSolutions demonstrates

Altair’s

expertise and capabilities as a concept-to-release, full vehicle

development partner.”

“We are thrilled to have partnered in the BUSolutions program

that is putting Michigan at the forefront of solving emerging

public transit technology issues through innovation and

collaboration,” said Ken Rogers, executive director at

Automation Alley. “Goals were set when this program started to

produce a transit bus that was more fuel efficient, more

affordable and more cost effective to operate for city transit

authorities, and this project has both met and exceeded those

goals.”

Additionally, BUSolutions strategically partnered with regional

and global high-tech manufacturers that assisted in

incorporating state-of-the-art components and technologies from

the transportation sector. Program sponsors include Parker and

Meritor, which contributed significant driveline systems and

knowledge. Various levels of support have been provided by PRAN,

Sika Corporation, Meritor Wabco, Alcoa Wheel Products, Carrier

Corporation, LADD Industries,Haldex, Shaw Development, Tenneco,

USSC Group, Cummins Bridgeway, Multicolor Specialties and

Williams Controls.

Altair has worked closely with local transit authorities, SMART

and DDOT, to ensure the newly designed bus platform will meet

regulatory requirements and address the needs of bus drivers and

riders. Altair also established the BUSolutions Advisory Board

to offer insight into broader community needs, as well as

perspective on actual ridership issues and public-interface

ergonomics. As a result, Altair ProductDesign successfully

engineered the bus to incorporate design principles that will

enhance the rider experience.

The LCO-140H Bus will also be demonstrated at the American

Public Transportation Association (APTA) Expo in New Orleans

Oct. 3-5 at booth #2281. For more information, visit the Altair

events website.

About BUSolutions

Launched in 2005, the Altair BUSolutions program was established

to develop and commercialize an advanced bus platform that

lowers the total cost of ownership and environmental impact of

commercial buses without updating the infrastructure of existing

transit authorities. Leveraging the company’s deep domain

knowledge in vehicle systems and cutting-edge, simulation-driven

design practices to develop the design, Altair successfully

partnered with Automation Alley, Michigan’s largest technology

business association, to secure federal funding to build working

technology demonstrators for future commercialization. For more

information, visit www.altairbusolutions.com.

About Altair ProductDesign

Altair ProductDesign is a global, multi-disciplinary product

development consultancy of more than 500 designers, engineers,

scientists, and creative thinkers. As a wholly owned subsidiary

of Altair Engineering, Inc. (www.altair.com), this organization

is best known for its leadership in combining its engineering

expertise with computer aided engineering (CAE) technology to

deliver innovation and automate processes. Altair ProductDesign

firmly advocates a user-centered, team-based design approach,

and utilizes proprietary simulation and optimization

technologies (i.e., Altair HyperWorks) to help clients bring

innovative, profitable products to market faster. To learn more,

please visit www.altairproductdesign.com.

|

|

|

Twin Cities Manufacturer

Part of the Solution to Stop Gulf Oil Leak

Modified valve from Continental Hydraulics Helps Waterjet System

Unclog Containment Dome

(Minneapolis, Minn.) – There’s no question the BP oil leak

crisis takes engineering, thought and industry best practices.

Intervention is rough according to James Miletich of

Oceaneering’s ROV Division. “You’re always fighting something.

It’s never easy,” he said.

Recently, hydrate ice crystals formed inside BP’s 40-foot-tall

containment system aimed to capture leaking oil—and ultimately

clogged the system. Hydrate gases crystallize like ice in cold

waters and high pressure deep beneath the ocean’s surface.

Minnesota company Continental Hydraulics, in partnership with

Jet Edge, Inc. and Chukar Waterjet, Inc. developed a solution to

help fight the problem. The company’s DO8 valve was used to

operate Jet Edge’s waterjet pump enabling the jet stream to

blast away the hydrate crystals.

“The timeliness and schedule was intense—but we were pleased to

deliver a modification to our product capable of withstanding

the harsh undersea environment and enormous water pressure at a

depth in excess of 5,000 feet,” said Continental Hydraulics

general manager Jeff Brandt.

Jet Edge’s custom engineered waterjet intensifier pump was

dropped into the sea to power a robot-operated waterjetting

lance— eliminating the hydrates. This equipment is the

first-known waterjet system capable of operating in water depths

in excess of 5,000 feet, opening a new frontier for waterjet

technology.

Chukar Waterjet, Inc. general manager Bruce Kivisto said, “We

worried about 2300 pounds of force and the harsh exposure to

that valve. Continental Hydraulics recognized the importance,

the challenge and delivered a critical component to our

success.”

Kivisto provided onsite application and engineering services

throughout the project, recently returning from several weeks

aboard a boat just 50 yards away from the Discoverer Enterprise.

He says the solution appears to be working and will continually

be monitored.

###

Continental Hydraulics of Savage, Minn. is a manufacturer of

high performance hydraulic pumps, valves and power units. Their

products are used in some of the most severe conditions and

their reputation for superior durability and performance

continues to grow. The engineering staff at Continental is

continually at work to improve current products and develop new

fluid power technologies. In addition, Continental Hydraulics

specializes in response time and delivery for challenging custom

orders. For more information, visit

www.continentalhydraulics.com.

|

|

|

Do Minor Oil Leaks Really Matter?

By Jack Weeks

We

are often asked if minor leaks are really much of a concern.

Repairing them takes valuable time that most maintenance shops

feel should be devoted to issues that could halt production.

Everyone knows that a ruptured hose needs to be addressed right

away. But the mistaken belief that a minor leak doesn't cause a

problem is certainly not uncommon. It is even a little

surprising how many people seem to believe that hydraulic

machines are "supposed to leak a little". We have heard

everything from "The oil that bypasses the cylinder seals helps

to keep the rods lubricated" to "The leaks in our system help

keep our oil fresh since we have to replace so much of it all

the time". These same people however would be dissatisfied if

their automobile's power steering pump, automatic transmission

or brake lines "leaked a little bit". We

are often asked if minor leaks are really much of a concern.

Repairing them takes valuable time that most maintenance shops

feel should be devoted to issues that could halt production.

Everyone knows that a ruptured hose needs to be addressed right

away. But the mistaken belief that a minor leak doesn't cause a

problem is certainly not uncommon. It is even a little

surprising how many people seem to believe that hydraulic

machines are "supposed to leak a little". We have heard

everything from "The oil that bypasses the cylinder seals helps

to keep the rods lubricated" to "The leaks in our system help

keep our oil fresh since we have to replace so much of it all

the time". These same people however would be dissatisfied if

their automobile's power steering pump, automatic transmission

or brake lines "leaked a little bit".

So how much does a minor leak cost? To answer that question, we

have to first explore all of the costs involved. Most people

think that the only cost is the amount of oil that has to be

unnecessarily replaced. But this is not the only cost associated

with hydraulic leaks. The actual costs include:

Replacement Oil

Safety

Environmental Concerns

Cleanup Costs

Disposal

Contamination

Loss of Machine Efficiency

Replacement Oil

This is the most obvious cost. A drop of hydraulic oil doesn't

cost very much even at today's prices. But if your machine loses

a drop of oil every second, it adds up. A drop every second will

equal about one gallon per day. 30 gallons per month and 365

gallons per year. Depending on your geographic area, the type of

oil you use in your machine and the volume you purchase you pay

between $6 and $10 per gallon. This means that a leak that loses

one drop per second (most machines lose many times that) is

costing you between $2190.00 and $3650.00 each year in

replacement oil alone.

Safety

The cost of replacement oil is bad enough but oil leaks pose a

safety hazard in almost every facility we have visited. The cost

of safety hazards is hard to calculate. But even one incident

can cost a few hundred dollars or a few million.

Environmental Concerns

Not everyone agrees with the Environmental Protection Agency's

standards and policies. But we doubt anyone believes that EPA

requirements will become more lenient in the near future. If any

changes are made in EPA standards, they are likely to include

stricter controls and heavier fines and penalties. Currently an

uncontained spill of more than one gallon can require EPA

notification. Fines in the millions of dollars are not uncommon.

Cleanup Costs

Often the costs of routine cleanup are ignored, but that doesn't

make them go away. Time devoted to cleaning up from a leak is

time that could be spent on more productive endeavors and could

result in overtime costs that would otherwise not have to be

incurred. And we cannot ignore the cost of cleanup equipment,

absorbent pads and detergents. Annual cleanup costs can easily

add $2000 or more to our drop-per-second leak.

Disposal

Those of us who can remember a time when waste oil companies

paid for the privilege of coming to empty our waste hydraulic

oil tanks can probably also remember getting change back from a

five dollar bill after having someone else fill up our gas

tanks, check our oil, check our tire pressure and clean our

windshield. These days an environmentally acceptable means of

disposing of waste oil can cost $3 per gallon or more. There's

another $1100 annual cost to our minor leak.

Contamination

It's easy to forget that if oil has a way out of the machine,

contaminants have a way in. Airborne contaminants, particles and

water all can wreak havoc with a hydraulic machine. Over 96% of

all hydraulic failures can be directly traced to contaminants in

the oil. Not all of those contaminants come from an oil leak of

course, but any that we can stop will pay big dividends in parts

that do not have to be changed unnecessarily, reduced down time

and greater intervals between flushing or changing the oil.

Loss of Machine Efficiency

A machine that leaks is working harder than it has to. This

means that, while the machine appears to be functioning as it

should, our energy costs have increased. Suppose our

one-drop-per-second leak causes the power bill to increase by

five cents per day. That's another $18.25 in annual cost. Not a

huge amount, but it could probably buy us dinner somewhere. And

it adds up if it occurs in several machines.

So assuming that no one gets hurt from slipping on oil and the

EPA doesn't have to visit, each drop-per-second leak is costing

somewhere between $5000 and $7000 every year. And hydraulic

leaks, unlike paper cuts, do not heal. They gradually get worse.

At some point, what starts as a "minor" leak can become a

machine outage. No leak is so minor that it should be ignored.

GPM Hydraulic Consulting, Inc.

Box 1376

Monroe, GA 30655

(770) 267-3787

www.gpmhydraulic.com |

|

|

- Funny Noises

By Jack Weeks

Not

long ago on a consulting job, I noticed a loud hissing sound

coming from a machine (not the machine I had been called to

help diagnose). I asked the man I was working with about it

and he said, "It's done that as long as I've been here. I

guess it's supposed to sound like that - the machine works

fine.". But it didn't sound normal to me. Looking a little

more closely, I noticed a very large, relatively new heat

exchanger installed on the machine. The man I was with

explained that the machine used to overheat, so they

installed a larger heat exchanger and that fixed the

problem. Watching and listening through a full cycle of the

machine, I noticed that the hissing sound was much louder at

idle than while the machine was running. Placing my hand on

the relief valve, I found that it was so hot I could not

keep my hand on it. The problem was obvious - at some point,

someone turned up the pressure on the pump compensator and

it was now adjusted above the system reliefvalve setting.

The pump was operating at full stroke all of the time. Any

flow not being used by the machine would dump across the

relief valve. I suggested that he reduce the setting on the

pump. I could tell that he didn't really want to, because he

was afraid the machine would stall. So I told him to wait

until the machine was idle again, then turn it down just a

quarter turn. Once the machine was in an idle condition, he

made the quarter turn counterclockwise on the compensator

and, with a puzzled look on his face, noticed that the

pressure reading on the gauge did not change. He made

another Not

long ago on a consulting job, I noticed a loud hissing sound

coming from a machine (not the machine I had been called to

help diagnose). I asked the man I was working with about it

and he said, "It's done that as long as I've been here. I

guess it's supposed to sound like that - the machine works

fine.". But it didn't sound normal to me. Looking a little

more closely, I noticed a very large, relatively new heat

exchanger installed on the machine. The man I was with

explained that the machine used to overheat, so they

installed a larger heat exchanger and that fixed the

problem. Watching and listening through a full cycle of the

machine, I noticed that the hissing sound was much louder at

idle than while the machine was running. Placing my hand on

the relief valve, I found that it was so hot I could not

keep my hand on it. The problem was obvious - at some point,

someone turned up the pressure on the pump compensator and

it was now adjusted above the system reliefvalve setting.

The pump was operating at full stroke all of the time. Any

flow not being used by the machine would dump across the

relief valve. I suggested that he reduce the setting on the

pump. I could tell that he didn't really want to, because he

was afraid the machine would stall. So I told him to wait

until the machine was idle again, then turn it down just a

quarter turn. Once the machine was in an idle condition, he

made the quarter turn counterclockwise on the compensator

and, with a puzzled look on his face, noticed that the

pressure reading on the gauge did not change. He made

another

quarter turn. Still no change. Then another and another. "I

don't think this valve is working - turning it has no effect

on the pressure.". But I could still hear the relief valve

dumping so I explained to him that the system pressure was

currently being determined by the relief valve, not the pump

compensator. After approximately one and one-half full turns

of the compensator adjustment, the hissing sound stopped.

The gauge pressure began to drop. I had him stop when the

pressure on the gauge was about 250 PSI below where it had

started. The machine was noticeably more quiet. "When it

starts back, I don't think it will work without stalling now

that we have the pressure this low.". I said,

"Let's see.". When the machine began to cycle again, not

only was it quieter than it had been, but the actuators were

moving faster than they had before. I also told him that the

current draw from the electric drive motor would likely be

considerably less than before, too. The original heat

problem had never really been addressed, only one of the

symptoms had been masked.

This is by no means an isolated incident. Hydraulic machines

simply do not make unusual sounds unless something is wrong.

Just because the machine still appears to be functioning

normally does not mean that it needs no attention. And a

strange sound coming from the machine is often one of the

very first signs of impending trouble. It has always been

amusing to me how the same person who would take his car

immediately to a mechanic if he heard a strange sound will

ignore unusual noises in a multimillion-dollar hydraulic

machine. Of course, there is no such thing as a silent

machine. All industrial machines make noise. But sound is a

form of energy and any unusual sound is, at the very least,

a waste of some of the energy applied to the machine. There

are hundreds of abnormal sounds a machine may make and an

exhaustive list of every possible one could probably

fill a book. All of them can mean trouble, but in a

hydraulic machine, a few of them are harbingers of serious

issues that can cost a lot of money in very little time.

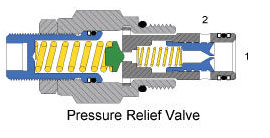

Relief Valves and Other Pressure Controls

Relief valves, for the most part, are designed to open only

when something is wrong. Typically they are installed to

keep system pressure from reaching dangerous levels With

only a few exceptions, hydraulic machines are not designed

to dump across their relief valves continuously. The hissing

sound described above and a significant temperature gain

across the relief valve are the most obvious indications

that a relief valve is dumping. Heat is also a form of

energy, so when a relief valve dumps a corresponding

increase in current draw will usually be indicated on the

electric drive motor. The excessive heat will not only waste

energy but will also degrade the hydraulic oil. Most relief

valves are set well above normal operating pressure, so when

they are dumping the system pressure is usually higher than

normal. This causes excessive wear all over the machine. If

left

unchecked, shock spikes attack hoses, fittings, pipe clamps

and seals. Mechanical wear to bushings, bearings, supports

and connectors is also accelerated. Other pressure controls,

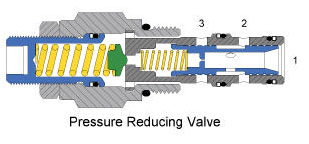

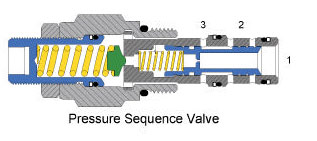

such as reducing valves and counterbalance valves are often

intended to be open regularly. But this doesn't mean they

should always make excessive noise. A whistling sound or

erratic hissing often suggests that they are improperly

adjusted or stuck open. A good rule of thumb is if it

doesn't sound right, it probably isn't. Slamming of

actuators, stalls and excessive heat generation are the

early symptoms of problems with these valves.

Pump Cavitation

A pump that is cavitating makes a steady, high-pitched

whining sound. Since the sound is steady and does not

reflect changes in the movement of the machine, it is often

confused with bearing wear in the pump. Often a pump is

replaced unnecessarily because it is cavitating. Cavitation

is caused when the pump is trying to deliver more oil than

it can draw into its suction line. This may be because the

oil is too cold and the viscosity is high or because the

drive motor has been mismatched and is turning the pump too

fast, but most of the time cavitation is caused by some

blockage in the pump suction. Usually this is the result of

a plugged suction strainer or filter. Naturally, when a pump

is

replaced, its suction filter element is changed or its

suction strainer is cleaned while everything is apart. The

cavitation stops when the new pump is installed, but

actually it was the cleaning of the strainer or the

replacement of the suction filter element that stopped the

cavitation.

In addition to the steady high pitched whining sound,

another symptom of cavitation is a reduced flow from the

pump, which will result in a reduced speed of the machine.

Obviously, a pump can deliver no more oil than it can get

into its suction line. The pump will destroy itself if the

cavitation is not addressed.

Pump Aeration

Often confused with cavitation because of its similar sound,

aeration occurs when outside air enters the suction side of

the pump. The pressure in the pump suction line is below

that of the surrounding atmospheric pressure, so a leak will

result in air coming in, not hydraulic fluid coming out. It

can be distinguished from cavitation by its somewhat more

erratic whining sound. The sound of cavitation is from the

implosion of air molecules suspended in the oil. Since the

molecules are distributed very evenly throughout the oil,

the sound of cavitation is very steady. But the amount of

air that leaks into the suction side of a pump is heavily

dependent upon the flow of hydraulic oil. The sound will

therefore change as changes occur in the machine. It will

also likely be accompanied by a sound similar to gravel or

marbles rattling around inside the pump. If you can view the

oil in the reservoir (most reservoirs have screens and

baffles that get in the way of seeing the oil) you may also

note some foaming of the oil. If a pump is allowed to aerate

it will wear rapidly. But beyond damage to the pump, the

rest of the hydraulic components will also be at risk.

Aerated oil causes a number of

problems. When air is in the line, the machine will perform

sluggishly (think about the last time you had air in the

brake lines of your car). Air viscosity is well below that

of oil. The reduction in viscosity will result in leaks,

faiure to lubricate and heat problems. Air also becomes

somewhat unstable at the high pressures hydraulic machines

are operated, so corrosion and seal damage are likely. Air

that enters the suction line probably also brings with it a

host of contaminants to damage components.

If a leak in the suction line is suspected, squirt oil along

the line. If aeration ceases briefly, you have found your

leak. A worn shaft seal on a fixed displacement pump can

cause it to aerate. Spray some shaving cream around the

shaft seal and see if holes are drawn into the foam.

Sometimes there is no float switch to shut the machine down

when the oil level is too low. If the level of the oil gets

too close to the suction strainer, a vortex will develop

drawing air into the suction line along with the oil.

Aeration can also be caused by the wrong shaft rotation or

by improperly aligned couplings.

Directional Valve Noise

For the most part, directional valves should operate quietly

- no more than a faint "click" on very quiet machines. The

small amount of noise a directional valve makes is almost

always completely drowned out by the rest of the machine. If

you can hear a directional valve spool shift, chances are

very good that there is a problem. If the pilot chokes are

improperly adjusted on a two-stage directional valve, it

will audibly slam when it shifts. The spool can easily be

damaged, but the greater issue is the shock it introduces to

the machine. Sudden movement of the valve spool causes shock

throughout the machine and the weaker points of the system

will suffer. Adjust the pilot chokes for smooth shifting of

the spool and greater component longevity.

Cylinder Noise

Cylinders should move with almost no noise. If a cylinder

makes noise, it may be binding or slipping. A bent rod will

wear seals and mechanical linkages rapidly. Slippage

degrades the performance of the machine and sends

contaminants from the resulting worn seals out to other

components. A noisy cylinder should be rebuilt or replaced

as soon as possible.

Hydraulic Motor Noise

Hydraulic motors can make many of the same noises as

hydraulic pumps. Just as pumps can aerate and cavitate, so

can motors. And the same results will develop. A motor that

is cavitating will destroy itself rapidly. This usually

occurs on motor drives that have loads that can be overcome

by gravity, causing the load to "run away". A meter out flow

control or brake valve can correct this.

Listening to a machine and paying attention to the sounds it

makes can pay off in large dividends by catching problems

early before they become outages.

Jack Weeks entered GPM’s organization in January of 1997 as

a CAD draftsman and hydraulic instructor. He has trained

thousands of electricians and mechanics in Hydraulic

Troubleshooting methods. His computerized animations have

made GPM's presentations and training CD's the recognized

leader in the industry. He received his education from the

Georgia Institute of Technology School of Electrical

Engineering and the Department of State Foreign Service

Institute. Jack is an experienced draftsman and taught

telecommunications equipment operation and repair for the

Central Intelligence Agency at American embassies overseas.

GPM Hydraulic Consulting, Inc.

Box 1376

Monroe, GA 30655

(770) 267-3787

www.gpmhydraulic.com |

|

|

The

"Hole" Story Behind Cartridge Valve Performance The

"Hole" Story Behind Cartridge Valve Performance

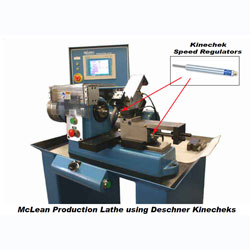

Latest precision bore machining technology drives performance

and quality improvements

by

Rich Moellenberg

Manager, Global Technology Support

Sunnen Products Company

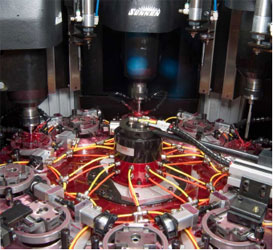

A new generation of honing technology is playing a vital role

today in improving product performance for fluid power

components, providing manufacturers a unique ability to

size and finish valve bores precisely, with exceptionally high

process capability (Cpk) levels. The new honing technology,

known as precision bore machining, can control bore size

with quarter-micron accuracy (0.00001 inch), correct geometric

errors in the bore, and produce a specific surface finish with

lubrication and seal enhancing properties.

What's this mean in terms of performance in a cartridge valve?

Conventional honing

straightens a valve bore and precisely sizes it. This allows

reduced clearance between the

bore and mating parts, greatly reducing valve leakage. The

tighter fit and correct geometry

help lower hysteresis and allow higher operating pressures with

overall greater system

efficiency. Finally, honing creates surface finishes that wear

at a slower rate to enhance

valve life. The crosshatch finish left by conventional honing

improves the uniformity of

the lubricating film between sliding parts for more consistent

performance, especially in

adverse operating conditions.

What is honing? Conventional honing is an abrasive machining

process whereby a tool

with expanding stone assemblies rotates in the cylinder bore,

while the tool or the part

reciprocates rapidly during the process. A conventional honing

tool may contact the entire

length of the part's bore, giving this process a unique

capability to correct geometric

error in the bore shape. Honing generates little heat and

stress, so the surface integrity

of the bore is excellent and can be finished to a specified

level of roughness.

It may seem a contradiction, but attaining performance

enhancements with honing

actually lowers costs for the valve maker and can create

opportunities to offer longer

product warranties. Here's how.

Any valve manufacturer can purchase basic screw machined

components from high-

quality vendors, but tolerances for these parts are rarely

"state of the art" precise. A

bore tolerance of 0.002 inch (0.05 mm) is considered acceptable

by most machinists, while

honing produces bore tolerances of less than 0.00005 inch

(<0.0013 mm).

In terms of the valve manufacturing process, various hole making

operations, such as

boring, drilling and reaming are capable of producing excellent

tolerances, but when a

manufacturer requires a high process capability – such as 1.33

Cpk – for quality purposes,

the acceptable tolerance level must shrink to meet this. For

rule-of-thumb purposes, when

the target is 1.33 Cpk process capability, manufacturers find

they have to hold about 75% of

the print tolerance; at 1.67 Cpk, it drops to about 60% of

tolerance, and the average of the

measurements needs to be targeted very tightly on the mean of

the tolerance. Holes produced

satisfactorily on a lathe for years that suddenly have to meet

process capability of 1.33 or

1.67 Cpk may require a much narrower bell curve of distribution

to stay between the upper

and lower support limits. "Flyers" at the fringes of the curve

become unacceptable.

How does "process capability" translate to real world results?

The classic Motorola

Six Sigma quality program (six sigma is a 2.0 Cpk process

capability) projected a defect

rate of 3.4 per million.

High process capability requires a machining operation that's

easy to "dial in" with

great precision, and very stable once the process is

established. For example, a lathe may

get to just a certain value, but if tweaked a little, will jump

to a value out of spec and

throws the process off. A computer-controlled hone can easily

get within 10 millionths of a

specified size, and with the resolution on the feed systems of

today's machines, the

variability is very small. Size control is not the only issue.

Honing allows tailoring of

the surface finish and then leaves a crosshatch pattern on the

bore of the cage.

Alternative processes, such as turning and single-pass honing,

cannot produce

conventional honing's characteristic crosshatch pattern on the

bore surface. Conventional

honing leaves a very desirable crosshatch pattern, which can be

visualized as two opposing

helical patterns that remain on the bore surface. This is the

same surfacing technology used

in automotive cylinder bores, particularly in performance

racing. The crosshatch pattern

can be controlled to produce a specific angle and depth, which

manufacturers use to control

the retention and distribution of lubricating oil films. A

crosshatch surface ensures a

consistent full-length flow path for lubrication around the

mating parts of the valve.

Conversely, bores finished with single-pass honing, or a

single-point tool will have

a faint, single helical pattern on the surface. The resulting

"threaded" finish can lead to

lubricating films being pushed out of the bore.

In addition to the crosshatch, honing also allows tailoring of

the bore's surface

finish to a desired spec. It seems contradictory, but an

ultra-smooth surface finish will

tend to diminish the lubrication between mating parts, actually

increasing frictional

resistance. It is common for manufacturers to monitor the

surface parameter Ra (average

roughness), but parameters such as Rk, Rvk and Rpk can also be

monitored – and controlled

with honing – to influence the performance of mating parts.

Conventional

honing improves the performance of valves by correcting

geometric error in the part, too. A conventional honing mandrel

– which contacts almost the full length of Conventional

honing improves the performance of valves by correcting

geometric error in the part, too. A conventional honing mandrel

– which contacts almost the full length of

the bore while the part reciprocates – can correct geometric

error (straightness, cylindricity) from screw machining, or

distortion from heat-treating or stress relief. In contrast, a

single-pass honing tool is tapered, so only a part of the tool's

length represents the final size. This part of the single-pass

honing tool tends to follow existing path of the bore, so a

curved bore will tend to remain unchanged. This is

especially true for parts with a length/diameter ratio exceeding

1:1.

The controlled fit, finish and clearance produced by honing

result in a more

efficient hydraulic circuit. The precision size and surface

finish help eliminate leakage.

Honing significantly reduces hysteresis and improves the

low-voltage reliability of

electrically actuated valves, an advantage for units installed

on mobile equipment.

What's on the horizon in honing technology? The latest

generation of machines is

designed to function as fully automated cells with integrated

air-gaging feedback for

closed-loop control of the process. It sorts parts by size after

processing, and all the

parts fall within a size range of 0.000125".

Glossary of terms

Cylindricity – The tolerance zone limited by two coaxial

cylinders a distance apart. A

typical spec would state: the toleranced cylindrical surface

shall be contained between two

coaxial cylinders 0.0002" (0.005 mm) apart.

Rk – The core roughness, or actual working roughness of the

surface that would be left after

the peaks have been eroded.

Rpk – The average peak height, which usually erodes quickly

during initial part cycles.

Rvk – The average valley depth, usually used for retention of

lubricating film.

Sunnen Products Company

7910 Manchester Ave.

St. Louis, MO 63143

Tel: 314.781.2100

|

|

|

|

|

Pressure Sensor Fundamentals

Associated with Hydraulic Systems

Hydraulic systems use incompressible liquids with low activation

pressure to control high pressure actions. From the brakes that

stop our automobiles, to fork lifts that move and stack heavy

boxes in warehouses, to the bulldozer moving dirt for the new

highway, hydraulic applications are all around us. When the

warehouse operator pulls the lift lever, he activates a

hydraulic pump that delivers fluid under pressure to a piston to

lift the load. The amount of fluid and pressure are a function

of the load. A heavier load requires the pump to increase the

pressure on the fluid to lift the load and the higher the load

is lifted, the more fluid is required to push the piston up.

The ability of a hydraulic system to match the amount of work

done by the pump to the size of the load is one of the defining

characteristics of a hydraulic system. In most systems, under no

load situations, no energy is expended by the hydraulic pump. A

light load may require only 15% of the capacity of the pump

while heavy loads can push the pump to the limit. In that way,

the amount of energy used to run a hydraulic system is dependent

on the load. The pump does not work full time at a fixed rate to

lift a light load.

There are few practical alternatives to hydraulics. Mechanical

systems could be designed with motors and gears but those

systems would have to be sized for the maximum load and would be

large and inefficient. Pneumatics or air pressurecould be used

in some applications but air compresses and any leak would

immediately deflate the system. The air compressor size and

power requirements would be significantly larger and more

complex than the hydraulic system. While hydraulic systems do

spring leaks, it takes time to drain all the fluid out of a

system through a leak and it can be detected and repaired before

damage is done to the operator or system.

Pressure sensors play a key role in hydraulic systems. They can

detect leaks in the system and insure that enough pressure is

available on demand to perform the job required. They can

provide a signal when the pressure exceeds system design

parameters or if the load is too heavy for the system to safely

handle.

Hydraulic systems are characterized by pressures of 6,000 PSI

and above. Pressure spikes caused by the pumps and the

applications can be significant and can easily double the

pressure that the sensor is expecting to see causing sensor

failure if not anticipated. Many times these pressure spikes are

of very short duration and require specialized equipment to

detect. The operating environment may see high vibration, severe

shocks and extreme temperatures. Because of the

severe environment, the technology used to build rugged and

reliable pressure sensors must be very robust. Pressure sensors

such as Kavlico’s P4000, PT250, and P5000 used in hydraulic

systems use welded, stainless steel construction. Pressure

sensors that use elastomeric compounds for the

main media seal present an opportunity for the seal to become

the weakest link and rupture, creating hydraulic fluid leaks. In

addition, the seal material may be incompatible with additives

or impurities used to optimize the base fluids.

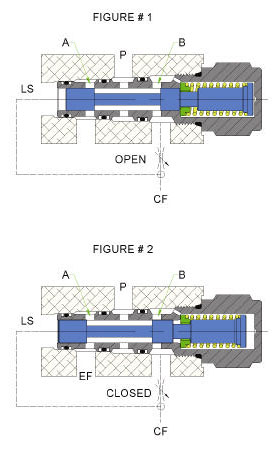

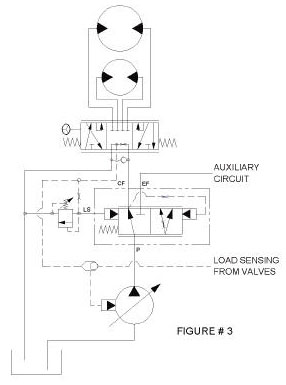

Piezo-Resistive

based sensors such as the Kavlico P4000 and P250 (Figure 1) use

welded oil filled headers with stainless steel isolation

diaphragms to protect the sense technology. Piezo-Resistive

based sensors such as the Kavlico P4000 and P250 (Figure 1) use

welded oil filled headers with stainless steel isolation

diaphragms to protect the sense technology.

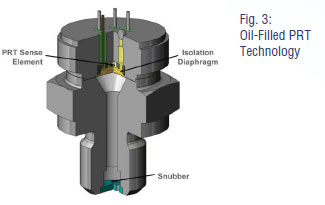

(Figure 3) is a cross section of the pressure media interface

for that type of product. The sense element is a high pressure

3,000 to 6,000 PSI piezo-resistive silicon MEMS device (PRT).

The PRT device consists of 4 resistors connected in a Wheatstone

Bridge configuration. It is mounted on a header

with glass feed-throughs for the external connection to the

leads of the silicon chip. The header is welded into a stainless

steel housing with an isolation diaphragm. The header structure

is filled with silicon oil and then sealed. As pressure

is applied against the diaphragm, it is transmitted to the

element by the incompressible oil. The MEMs device provides an

output proportional to pressure that can be amplified and

conditioned by an ASIC inside the sensor body. The structure can

be made more robust by adding a pin hole sized snubber of the

pressure spikes by providing a restriction followed by an

expansion chamber inside the thread in front of the diaphragm.

These types of pressure sensor are optimized for pressure

ranges between 1,000 and 5,000 PSI and are appropriate for less

price sensitive medium to lower volume applications.

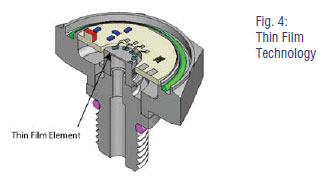

Higher

volume and higher pressure applications are serviced by thin

film technologies such as those found in the Kavlico P5000

(Figure 2) series. The cross section of a thin film unit is

shown in (Figure 4). A stainless steel piece is hollowed out to

provide a thin diaphragm and materials are deposited on the top

of that piece of steel. Resistors are implanted into the thin

film in a Wheatstone Bridge arrangement and the pressure Higher

volume and higher pressure applications are serviced by thin

film technologies such as those found in the Kavlico P5000

(Figure 2) series. The cross section of a thin film unit is

shown in (Figure 4). A stainless steel piece is hollowed out to

provide a thin diaphragm and materials are deposited on the top

of that piece of steel. Resistors are implanted into the thin

film in a Wheatstone Bridge arrangement and the pressure

applied to the hollowed out side of the steel is transferred to

those resistors, upsetting the bridge. The thin film elements

are welded into stainless steel housings and appropriate signal

conditioning is added to complete the sensor construction. It is

not uncommon to find thin film elements rated as high as 20,000

PSI which would be impractical in other sensor technologies.

The

electrical, temperature and stability performance of the product

is defined by the materials used. The unit output is smaller

than that of a comparable silicon PRT structure and must be

amplified to a usable output voltage range. Nickel The

electrical, temperature and stability performance of the product

is defined by the materials used. The unit output is smaller

than that of a comparable silicon PRT structure and must be

amplified to a usable output voltage range. Nickel

Chromium films are widely used by many suppliers. Newer Titanium

Oxynitride (TiON) films used in the P5000 provide almost twice

the electrical output per applied pressure as more conventional

materials allowing for higher stability underhigh temperature

operation.

There is no single best approach for all hydraulic pressure

sensing applications. Maximum pressure range, cost targets,

physical size, output configuration, safety considerations and

temperature range are all factors that must be evaluated in any

system design.

For more information contact:

Kavlico

14501 Princeton Ave., Moorpark, CA 93021

Tel: (805) 523-2000 – Fax: (805) 523-7125

Web: www.kavlico.com – E-Mail:

sales@kavlico.com

|

|

|

|

How

Long Should Hydraulic Hose Last? How

Long Should Hydraulic Hose Last?

By Jack Weeks

GPM Hydraulic Consulting, Inc.

How long should the hoses in a hydraulic machine last? Well, the

short answer is that it depends. Some people are surprised to

find that hose material has a shelf life and that it can be

affected by factors such as temperature, humidity and

ultraviolet light exposure of the area where it is stored. This

differs by hose type and manufacturer of course, but that is not

what our customers usually mean when they ask about hose life.

When a hose is replaced on a hydraulic machine, we would like to

know about how long we can reasonably expect this hose to stay

in service.

Unfortunately, hose life can be very hard to predict. There are

simply too many variables between machines to make any sort of

blanket statement. But if you find yourself changing the same

hose over and over again while the other hoses on the machine

seem to be immortal, it is definitely time for some further

investigation to determine what deteriorating factors are

affecting that particular hose and not the others.

Naturally hoses will not last forever. And certainly they will

not last as long as hard pipe. Wherever possible, long hose runs

should always be replaced by hard pipe, terminating with a

length of flexible hose into.components to absorb shock. But

some applications demand hoses and we would like for them to

last as long as possible. So even if we can't predict hose life

with any accuracy, we can at least be sure that we get the

maximum possible life from the hose. Here are a few of the most

common mistakes we find that can shorten hose life expectancy:

Using the wrong size hose. Sizing the hose is more than cutting

it to the right length and putting on the right fitting. Hoses

are designed for specific flow rates, pressures and

temperatures. If we deviate from their specifications, hose life

can suffer. While that statement may appear blatantly obvious,

we often find that hose specifications have been ignored -

sometimes inadvertently and sometimes deliberately. Most plants

stock hose in various diameters but not of different

characteristics. Sometimes this one-size-fits-all approach gets

us in trouble, particularly when a new machine is installed that

requires hose with different specs. The same hose that is used

everywhere else in the plant eventually gets used on this new

machine with disastrous results. Since there is only one type of

hose in stock, no one is likely to check to see if it suits the

needs of the machine - it has to, that's the only one we have!

Sometimes the wrong hose is deliberately installed. We have seen

hose that is too small in diameter installed in an attempt to

make the machine run faster. A common misconception is that

smaller diameter hose results in a higher flow rate. Higher flow

rate, of course, does increase speed. The problem with this plan

is that a higher flow rate cannot be obtained by undersizing

pipes or hoses. Hose diameter affects fluid velocity, not flow

rate. No matter how small the hose, if you put 10 GPM into it,

you can get no more than 10 GPM out of it. Increasing the

velocity will however add heat and turbulence to the machine.

Not only will this damage the inner metal tube (especially at

bends), it can also cause premature failure of hydraulic

components in the machine. At one plant, the technician was so

insistent that we were incorrect about this that he timed the

movement of the actuators in the machine. They did in fact move

faster than they had with the correct larger hose. Only once we

pointed out that the system temperature had increased by 37oF

did he understand the real reason the speed had increased. He

could have had exactly the same speed increase (without the

additional turbulence) by turning up his oil heater. Yet he was

horrified at the suggestion of doing this! As well he should be

- whenever the speed of a machine can be increased by raising

oil temperature, there is an orifice that can be opened instead.

But that's a different article.

Some people over size hoses as well. This in an an attempt to

keep fluid velocity and temperature at a minimum. There is merit

to this, but also a point of diminishing returns. As long as

your hose meets the requirements of the system, you will

probably not get enough benefit to justify the cost of the

larger hose. Add to that the problem of making a larger hose fit

the application, causing bends at the fitting and increasing the

chance of the hose rubbing on another surface or another hose

and suddenly oversizing our hoses no longer sounds like such a

great idea.

Often hoses are cut too long for the application. When we

replace a single hose, we want to be sure we have enough hose so

we only have to do it once. So the tendency is to cut the hose

longer than we need. Thus hoses tend to "grow" over a period of

time. In our hydraulic classes, we teach that most hoses (with

exceptions of course, such as traveling cylinders) should be no

longer than about four feet. But this is not set in stone - by

and large, a little common sense can prevail here. Most of the

time, if a hose installation looks good, it is good. But if the

hose is rubbing against something, snaking around the floor, has

unnecessary bends or is jammed into too small of a space,

perhaps it needs some attention.

Failing to take into account the abuse a hose will suffer. Hoses

are not indestructible. They should not be installed in such a

manner as they are likely to be stood on, run over by a forklift

or rub against another hose or surface. If subjection of a hose

to a hazard is unavoidable, there are many options available to

protect it. If a hose must be installed close to a heat source,

for instance, a metal heat shield should be installed to protect

it. If abrasion cannot be avoided, use a protective cover.

Ultraviolet rays from the sun can badly degrade hose material,

so if it must be subjected to the elements, protect it.

Just as water and other contaminants in hydraulic oil can damage

components, so can they damage hoses. And whenever we have a

choice between installing a hose to run vertically or

horizontally, the horizontal installation will cause less pull

on the hose fittings.

Forgetting about shock spikes when specifying hose. All too

often, we have seen hoses installed that are underrated. A

machine that operates at 1500 PSI should not have hose rated for

only 2000 PSI. It is not uncommon at all for shock spikes to

reach several thousand PSI above the operating pressure of a

machine. The OEM can recommend the proper hose pressure rating.

And if we use the OEM recommended hose, be sure we set the

system pressures to the OEM recommendation as well. A pressure

setting that is 200 PSI too high will result in shock spike

increases of much more than that. Keep shock spikes to a minimum

by making sure the pressures are set correctly and keeping

components that absorb shock in good repair.

Using an incompatible hydraulic oil. All hydraulic oil is not

the same. A wide range of additives is available. Before trying

a new oil, be sure to ask your oil vendor if it could damage the

hoses.

Neglect. An inspection of all of the hoses should be performed

at least monthly. Signs that a hose is about to fail such as

bubbling of the outer hose, loss of flexibility, cracks,

discoloration or signs of abrasion are easy to spot. It is

always better to replace the hose before it fails. If the hose

fails during production, not only will production time be lost

but it is likely that the ruptured hose will damage something

else. Anyone who has ever witnessed a hydraulic hose breaking

knows that it is not something to be taken lightly. Tremendous

force is released (and a lot of hot hydraulic oil). If your

hoses have lasted a year or two, consider yourself fortunate and

replace them whether they appear to need it or not. And if a

hose is located where someone could be injured or killed if it

fails, a much closer change interval is justified.

Jack Weeks entered GPM’s organization in January of 1997 as a

CAD draftsman and hydraulic instructor. He has trained thousands

of electricians and mechanics in Hydraulic Troubleshooting

methods. His computerized animations have made GPM's

presentations and training CD's the recognized leader in the

industry. He received his education from the Georgia Institute

of Technology School of Electrical Engineering and the

Department of State Foreign Service Institute. Jack is an

experienced draftsman and taught telecommunications equipment

operation and repair for the Central Intelligence Agency at

American embassies overseas.

GPM Hydraulic Consulting, Inc.

Box 1376

Monroe, GA 30655

(770) 267-3787

www.gpmhydraulic.com

|

|

|

|

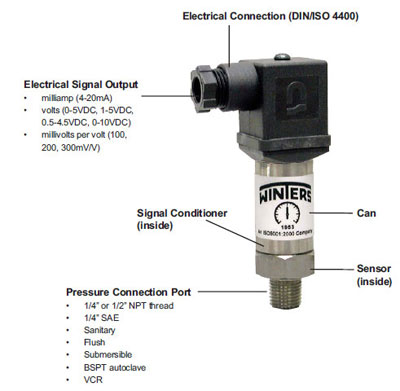

Selecting a Pressure Transmitter

Selecting the correct pressure transmitter for the appropriate

application can be a complex task, and failure to do so can make

the operation of the equipment ineffective and possibly

hazardous. Please read below to gain a better understanding of a

transmitter’s various components and parameters.

Transmitters can be thought of as electronic pressure gauges.

There are two kinds of electronic pressure gauges: pressure

transmitters and pressure transducers. The general difference

between a transmitter and transducer is the electrical output,

where a transmitter outputs signals in milliamps (mA) and a

transducer outputs signals in volts (V) or millivolts per volts

(mV/V).

The

two primary areas to focus on when selecting a pressure

transmitter are the operating conditions (environment) and

performance requirements. The

two primary areas to focus on when selecting a pressure

transmitter are the operating conditions (environment) and

performance requirements.

Operating Conditions

Knowing where the transmitter will be operating in and choosing