Bluetooth

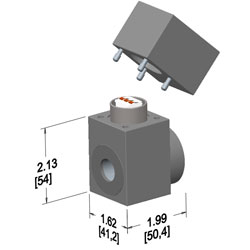

Embedded Amplifier Bluetooth

Embedded AmplifierConfigure your Bluetooth Embedded Amplifier with AmpSet BlueTM Sun’s new Bluetooth Embedded Amplifier is the fluid power industry’s first commercially available Bluetooth-configurable product, providing a compact, factoryintegrated coil and connector combination for use with Sun’s proportional solenoid valves. Users can configure the embedded amplifier wirelessly via our new app, AmpSet Blue™, using iOS and Android mobile devices for quick, easy, and reliable wireless calibration. This groundbreaking development in the fluid power cartridge industry means that operators can now be in close proximity to observe valve operation but not tethered and completely safe when setting up and calibrating the machine behavior. AmpSet Blue™ allows users to locate and ‘pair’ with the selected amplifier using their smart device and adjust all parameters of the proportional controller through several simple screens. Users can name each device and save, store, recall, and share settings for future use. Ideal for multi-valve systems and hard-to-reach or dangerous environments, the app can pair with the Bluetooth Embedded Amplifier from as far away as 30 feet. It eliminates the need to carry a separate programmer or expensive laptop and special cables into a hazardous environment. Features: -Bluetooth embedded controller rated at IP69K; CE and RoHS compliant -Free easy-to-use smart device app for configuration and adjustments -Password protection built in to prevent unauthorized access -Simple, safe, and secure Password protection prevents unauthorized access to the amplifiers. And for added safety, a “connection time-out” feature is activated by a period of inactivity, preventing the user from leaving the application open and paired. Coils are available in both 12 and 24 VDC with a choice of Deutsch or ISO DIN connectors. See our listing of Bluetooth Embedded Amplifiers. For iOS devices, search on “Sun Hydraulics” in your app store today to download Sun’s AmpSet Blue™ app and start configuring without wires. For Android devices, please visit our AmpSet Blue™ app download page. Note: The Bluetooth app is for set-up only, is not intended for continuous use, and cannot be used for remote commands or powering the amplifier. A power cable is required to provide power to the unit. Sun Hydraulics

Corporation |

|

Modular

Hazardous Coil Modular

Hazardous CoilThe MH Coil is a solenoid coil designed for use on cartridge valve assemblies with applications in hazardous or explosive environments. -Fin-free design to prevent build-up of grease, dust, and debris -Featuring a selection of on-off proportional options -1/2” NPT or M20 x 1.5 conduit connections -Vibration resistant push to connect terminal block visit gwlisk.com to learn more about our family of hazardous location solenoid products. G.W. Lisk Company, Inc. 2 South Street Clifton Springs, NY 14432 Phone: (315) 462-2611 Email: info@gwlisk.com

|

|

Star

Hydraulics introduces 1 Ton Hand-Operated Hydraulic Lift-Jack Star

Hydraulics introduces 1 Ton Hand-Operated Hydraulic Lift-JackIn a single, compact lightweight unit, Star has combined an efficient pump and durable cylinder that produces 2,000 pounds of lifting capacity. The model HH700 Jack is easy to operate. It takes only 1.5 pounds of lift force per 100 pounds of load. For each stroke of the pump lever, the cylinder piston rod moves .16 inches. This lift jack has a built-in release knob for rapid lowering. Star provides stroke lengths from 7 inches to 25 inches to fit the needs of your application. Visit http://www.starhyd.com for more information.

|

|

HAWE

Hydraulics is a leading global manufacturer and supplier of

sophisticated hydraulic components and controls for the mobile,

industrial, and renewable energy markets. HAWE

Hydraulics is a leading global manufacturer and supplier of

sophisticated hydraulic components and controls for the mobile,

industrial, and renewable energy markets.“The PSL/PSV valve series is just one of the many components HAWE Hydraulics displayed at the ConExpo/IFPE Tradeshow in Las Vegas, NV. HAWE offers a proportional directional spool valve type, PSL/PSV that can be configured to easily satisfy all the necessary hydraulic functions of a silage trailer. These functions include, but are not limited to, raising/lowering the tailgate or front gate, and operating the scraper floor drive and conveyor drive systems. Unique modular designs allow this valve series to be configured for tractors with fixed or variable displacement pumps and permits easy adjustments via manual, remote hydraulic pilot or electrical control. Their compact design allows them to be deployed in applications where space is at a premium and consolidation is necessary. The PSL/PSV’s flange mounted design simplifies plumbing/hose runs and uses a twin solenoid configuration, unique to HAWE, that reduces wiring and allows for both proportional and on/off operation. These “load-sensing” valves are designed to keep the input pressure constant without being effected by the individual work units. This permits independent pressure control between the work sections/functions of the valves. Independent pressure control allows for greater efficiency since the only power consumed is that which is required to do the physical work of each separate function, thus saving fuel and enabling precise motion control for the consumer. Operating pressures of up to 420 bar and maximum flows up to 200 lpm make the PSL/PSV a practical solution for agricultural machines which normally operate at pressures around 200 bar.” HAWE Hydraulics 9009-K Perimeter Woods Dr. Charlotte, NC 28216 Tel.: +980-207-5642 Fax: +704-509-6302

|

|

Eaton

Highlights Customers’ Successes with New X20 Challenge Eaton

Highlights Customers’ Successes with New X20 ChallengeEDEN PRAIRE, MINN. … Power management company Eaton today announced the X20 Challenge, encouraging the company’s customers to submit success stories highlighting where Eaton’s X20 portfolio of piston pumps have positively impacted a customer platform or application. One story will be chosen each quarter and will be featured in the company’s X20 portfolio advertising and social outreach campaign. “One of the most interesting things as an Eaton employee is hearing about how our customers are using these products around the world,” said David Strohsack, global mobile portfolio marketing director, hydraulics business, Eaton. “Whether it’s a snow groomer in Europe, combines in Russia or concrete mixers in North America, our customers are applying the X20 portfolio in ways that we didn’t even imagine. And they’re saving money. With well over 100,000 units in the field today, we know our customers are putting X20 to work in many unique ways, solving unique problems and we are looking forward to hearing more.” Customers are encouraged to take the X20 Challenge and submit their stories via the X20 Challenge website. Additional information about the Challenge – and Eaton’s Hydraulics Business – can be found on the new @ETN_Hydraulics Twitter handle and the Eaton-Hydraulics/X20 LinkedIn showcase page. Challenge participants can get the latest news by following the hashtag #X20Challenge on Twitter. The X20 portfolio represents Eaton’s most modern version of variable displacement piston pump technology that includes a 220, 420 and 620 displacement range. Since the 420 was launched in 2005, Eaton has sold thousands of pumps to OEMs in the agriculture, materials handling, commercial vehicle and construction markets. To learn more about the X20 portfolio and the X20 Challenge, visit www.eaton.com/X20. Eaton is a power management company with 2013 sales of $22.0 billion. Eaton provides energy-efficient solutions that help our customers effectively manage electrical, hydraulic and mechanical power more efficiently, safely and sustainably. Eaton has approximately 102,000 employees and sells products to customers in more than 175 countries. For more information, visit www.eaton.com.

|

|

VP120

Directional Control Valve Reduces Fuel Consumption for Mobile

Equipment VP120

Directional Control Valve Reduces Fuel Consumption for Mobile

Equipment LAS VEGAS, March 4, 2014 – Parker Hannifin Corporation, the global leader in motion and control technologies, presents the VP120 valve, designed to utilize contemporary flow-sharing technology to address problems associated with pump over-demand conditions. The development of the VP120 diversifies and strengthens Parker Hannifin’s industry-leading line of mobile hydraulic valves. This newly designed valve provides improved horsepower utilization, reduced fuel consumption and trouble-free operation. It also features innovative product options such as flow sharing with individual pressure limitation and expert/novice control settings, allowing for multiple operators to have different functional settings and speeds. Rated for a maximum pump input of 160 liters per minute (LPM), 42 gallons per minute (GPM), and a work-section output range of 15 -120 LPM (4-32 GPM), the VP120 is the industry’s most power-dense valve product in its flow category, saving both cost and weight. Using advanced finite element modeling and computational fluid dynamics, the VP120 is rated to 280 Bar (4060 PSI). The modular design of the VP120 enables features to be added or removed, depending upon the application. This flexibility ensures an optimized value match for the machine. For example, it can be configured for load-sense pressure compensation or for load-sense only, which means you don’t have to pay for hardware that does not add value to your machine. For commonality the VP120 shares all of the relief valves and tie bolts from other valves within Parker Hannifin’s product offering. The VP120 is an excellent choice for applications with pump input flows from 18-160 LPM (5-42 GPM). Its target markets include construction, aerial work platforms and refuse. Ideal machines are wheel loaders, dozers, cranes, backhoes, digger derricks, truck-mounted aerial work platforms, mini excavators and automated side loaders. Some key features and benefits of the VP120 Include: advanced machine controllability due to predictable metering; improved system efficiency with up to 30 percent fuel savings; flow-sharing technology that enhances machine productivity; flexible design; wide flow range; induced load protection; a bypass unloader option; cavitation reduction; margin control; and individual pressure limitation. Parker’s worldwide network of field sales engineers and distributors offer hands-on, local customer support. For more information on application of the VP120, call 1-800-CPARKER

|

|

NOSHOK

ANNOUNCES THERMOWELLS FOR NOSHOK

ANNOUNCES THERMOWELLS FORINSTRUMENT PROTECTION NOSHOK thermowells, in conjunction with temperature measurement instrumentation, allow the user to remove and replace instrumentation without having to shut down the process. NOSHOK thermowells protect instrumentation from damage or failure due to corrosive, erosive, high pressure, and high velocity flow applications. This is important in tank or vessel applications as well as critical process piping involving pressure measurement. It is also crucial in applications where temperature needs to be measured and pressure is a factor, such as boilers, power generators and turbines. The stems on NOSHOK bi-metal thermometers, 800 Series Temperature Transmitters, 820/821 Series Digital Temperature Indicators, 850 Series Electronic Indicating Transmitter/Switches, and 900/910/915 Series Industrial RTDs are rated to 600 psi in ambient conditions. In applications where both pressure and temperature are a factor, thermowells should be used in conjunction with these instruments when pressure exceeds these values. Thermowells are also useful if a flanged, sanitary, or weld-in process connection are required. ½” NPSM instrument connection, ¾” process connection standard - other options are available including flanged, socket weld, sanitary etc. The female connection accepts the ½” NPT male thread without galling or seizing Brass, 304 stainless steel, or 316 stainless steel are standard material options - other material options are available Stepped shank standard, tapered or straight available on request 0.260” bore standard - others available on request Lagging extensions available on request Other options include plug and chain, special coatings (PTFE, PVDF), hydrostatic testing, velocity calculations, NACE

|

|

|

A BP Series heat exchanger is one of the most efficient ways to transfer heat today. Our BP Series heat exchangers are rugged, compact, cost-effective and reliable over long periods of time with minimal maintenance – an optimal heat transfer solution for compact industrial applications. 316 stainless steel construction and standard SAE connections are features of this highly efficient technology. The compact design and multiple mounting options lead to optimization of heat transfer when space is limited. High plate channel turbulence means effective performance even with close approach temperatures. Our wide offering of standard models ensures fast delivery worldwide. Custom applications always welcome! Thermal Transfer

Products

|

|

Goodway Technologies Corporation

|

|

FilterMag CT:

Powerful—Focused—Magnetic Field Technology

|

|

|

New Grip Plugs GPN 607 from

Poppelmann USA Time-saving: Practical tab for easy removal. Multi Functional: The tapered design is ideal for accomodating large tolerances. Temperature resistant: Heat resistant to 250°C. More details: page 101, “Physical properties“. Leak Proof: Prevents penetration of liquids within certain limits. Additional information: Suitable for bore holes and internal threads. Particularly suitable for painting. Material:Silicone (SI) Colour:natural Poppelmann Plastics USA LLC 2180 Heart Drive P.O. Box 459 Claremont, NC 28610 Phone: +1 828-466-9500 Toll free: +1 866-886-1556 Fax: +1 828-466-9529 E-Mail: info@poppelmannUSA.com

|

|

Single-Stroke Cylinder Type Intensifier

from IC-Fluid Power. The

Hänchen intensifier is a custom, heavy-duty, pressure

intensifier designed for non-standard applications. This model

allows the input fluid to be the same as, or different than, the

output fluid as a result of its non-reciprocating, axial type

construction. The

Hänchen intensifier is a custom, heavy-duty, pressure

intensifier designed for non-standard applications. This model

allows the input fluid to be the same as, or different than, the

output fluid as a result of its non-reciprocating, axial type

construction.Specifically, the primary cylinder can be run with mineral oil and the secondary chamber can be run with a different fluid such as water or water containing media. This type is commonly found in the hydroforming industry. IC-Fluid Power, Inc. 63 Dixie Highway PO BOX 97 Rossford, Ohio 43460 Telephone: +1.419.661.8811 Fax: +1.419.661.8844

|

|

The Wilkes and McLean Noise

and Shock Suppressor is

manufactured

in Illinois manufactured

in Illinoisand assembled in our Schaumburg, Illinois facility. Our patented design is proven to eliminate up to 90% of hydraulic pulsations, greatly reducing noise and vibration. The Wilkes and McLean Suppressor can benefit any hydraulic system and will separate you from the competition. KEY BENEFITS • Eliminates Pulsations • Reduces Noise • Absorbs Hydraulic Shock • Increases longevity • Reduces Vibration • Easy inline install • Competitive advantage • Multiple Configurations • Great for Retrofits Wilkes & McLean, Ltd. 600 Estes Ave. Schaumburg, IL 60193 Toll Free Phone: 877-534-6445 Phone: 847-534-2000 Fax: 847-534-2016

|

|

WEBTEC

introduces the new HPM4000 series hydraulic data logger. WEBTEC

introduces the new HPM4000 series hydraulic data logger.The HPM4000 series is a highly versatile entry-level portable hydraulic data logger, ideal for pre-dispatch inspection, preventative maintenance and simple diagnostic fault-finding. There are two models, Sensor Recognition (SR) & Intelligent Digital (ID). 1290 E. Waterford Ave. Milwaukee 53235 Wisconsin U.S.A. Telephone: +1-800-932-8378 Fax: +1 414-769 6591 e-mail: sales-us@webtec.com

|

|

Hydraulic

Weight Balancing Saves Electricity Hydraulic

Weight Balancing Saves ElectricityCHARLOTTE, N.C.– November 4, 2013– HAWE Hydraulics, a leading global manufacturer and supplier of sophisticated hydraulic components and controls for the mobile, industrial, and renewable energy markets. For large machining centers, balancing the weight of spindle heads and work piece tables pays off. HAWE Hydraulics develops unique solutions that are both energy efficient and durable. These solutions reduce energy consumption while lowering the total costs of ownership for these types of machines. When combined with Hawe Hydraulics’ counterbalance valves even greater electrical power savings can be achieved. Hydraulic weight balancing is an automatic process. Once the system is pressurized it no longer requires additional energy input. The hydraulic cylinder is connected to the accumulator which takes up the weight of the spindle head and/or work piece table. The pressure is set so the cylinder balances the weight and only the friction force and inertia mass must be overcome to move the spindle head along its axis. This balancing of the spindle head and/or work piece table requires significantly less power to drive, thus lower power consumption. HAWE Hydraulics provides a broad line of potential solutions to accomplish this; more commonly used is the compact MPN power pack. The MPN Power unit provides high operating pressures for filling/emptying the system and therefore, permits a larger tank volume. This can all be accomplished while maintaining a compact footprint. The MPN power pack can be configured with a variety of valving combinations and is deliverable as a complete system to meet all your hydraulic weight balancing applications. About HAWE Hydraulics North America: Sixteen years ago North America was introduced to HAWE Hydraulik through its American subsidiary HAWE Hydraulics. Today, the partnership brings more than 60 years of German engineering and experience to North American mobile and industrial markets. HAWE provides integrated services that include design, manufacture, set-up, a distributor network, and local inventory. Based in Charlotte, NC, HAWE Hydraulics is positioned to respond quickly to service needs, as well as provide prototypes in a timely manner. Headquartered in Munich Germany, HAWE Hydraulik is an ISO 9001:2000 certified international supplier with a strong focus on supporting rapidly developing niche markets.

|

|

The

DPX Series Full Flow Sharing sectional valves. The

DPX Series Full Flow Sharing sectional valves.

The DPX Series, a complete range of Load Sensing Flow Sharing valves, answers the needs of the modern Construction Industry where high efficiency, high pressure conditions, and reduced energy consumption are required.The DPX100/HF Flow Sharing sectional valve adds a high flow option to the DPX100 (Work Port Nominal Flow: 31.7 US GPM, Work Port Max. Pressure: 6000 psi). The High Flow option allows the DPX Series to provide the features of Load Sensing and Flow Sharing Technologies, control, energy savings, and longer system life, to an expanded range of possible applications. Walvoil Fluid Power Corporation 4111 North Garnett Tulsa, OK 74116, USA TEL. 001 918 858 7100 . FAX 001 918 858 7150 email: info@walvoilfluidpower.com

|

|

|

|

|

MICO, Incorporated introduces a trailer brake

Load-Apportioning-Valve (LAV) for use with MICO MOBEUS EH brake

systems on Agriculture and other Off-Highway vehicles and

trailers. The new LAV proportions trailer brake pressure

utilizing a tow vehicle’s hydraulic brake signal in conjunction

with real-time trailer load sensing to continuously control

pressure-reduction braking to the trailer brakes without

utilization of tank-pressure. The result is load sensitive

trailer braking that reduces the occurrence of trailer wheel

lock-up or skidding.

|

|

Tobul’s

Piston Accumulator: Options for All Tobul’s

Piston Accumulator: Options for AllTobul Accumulator has

developed several distinct families of standard piston-type

products, based on physical dimensions, MAWP (Maximum Allowable

Working Pressure), and fluid volumes; all to best suit customer

needs. Tobul accumulators can be adapted with, a variety of raw

materials (carbon steel, stainless steel and special alloys),

seal configurations and compounds (Buna-N, EPR, Viton, Kalrez®,

Teflon®, etc.), and fluid and gas port configurations, to suit

individual applications. This makes Tobul “A Name for Excellence

in Fluid Energy Control.”

|

|

Intrinsically

Safe Pressure Transmitters Meet CSA Demands Intrinsically

Safe Pressure Transmitters Meet CSA Demands

Gems Sensors &

Controls announces the introduction of the 31CS and 32CS Series

intrinsically safe pressure transmitters. These series have been

approved by CSA to the standards required for both USA and

Canadian use in hazardous areas. The two new Series are

identical, with the exception of the pressure diaphragm. 32CS

Series transmitters feature a thicker diaphragm and a pressure

restrictor to withstand the rigors of cavitation or extreme

pressure spikes, improving stability and reliability in

pulsating applications.

|

|

Brennan

Industries Introduces New Selection of Instrumentation Valves Brennan

Industries Introduces New Selection of Instrumentation Valves

Brennan Industries, Inc., a leading international supplier of

hydraulic fittings and adapters, expanded its product lines by

introducing new instrumentation valves.

|

|

Metaris

Announces new Orbital Motors Metaris

Announces new Orbital MotorsThe Latest and Greatest

|

|

Revolutionary

sealing material Turcon® turns 50 Trelleborg Sealing Solutions

launches celebration to commemorate anniversary Revolutionary

sealing material Turcon® turns 50 Trelleborg Sealing Solutions

launches celebration to commemorate anniversary>From airplanes to spacecraft, prosthetics to wind turbines and almost everything inbetween, Turcon® is the go-to seal material for a broad range of applications. This revolutionary material is a part of—and has made possible—some of the most innovative engineering advancements in the last half-century. Now, on the eve of the PTFE material’s 50th anniversary, Trelleborg Sealing Solutions is commemorating the material’s impact on the world. Trelleborg Sealing Solutions has brought together customers such as Boeing and Eaton; former executives from Busak+Shamban and Trelleborg; and engineers, researchers, manufacturers and others who have been involved with Turcon® over the years for a multimedia retrospective. The project unfolds in stages. A website with photos, videos and first-person contributions from a variety of people in the industry debuts in May. The project also includes a commissioned, hand-painted mural showing Turcon®’s impact over the decades. Once a month, from May 2012 to January 2013, Trelleborg Sealing Solutions will reveal the next panel in the mural, along with relevant photos, videos and other media. “The brand started with W.S. Shamban in 1962 and if you look at all the engineers who are in the market today, they don’t recognize the Trelleborg name with the Turcon® brand,” says Nancy Getz, Product Manager of Trelleborg Sealing Solutions Fort Wayne. “That’s what makes this anniversary so important.” Turcon® has a long history tied tightly to the Fort Wayne community; it was developed by Bill Shamban, founder of W.S. Shamban Co., which moved to Fort Wayne in 1956. Turcon® was produced in Fort Wayne facilities under the W.S. Shamban Co. and Busak+Shamban names, and now by Trelleborg Sealing Solutions. The name has changed, but the quality standard and respect for its history remain the same. Turcon® is a proprietary polytetrafluoroethylene-based (PTFE) sealing material introduced by Bill Shamban and Hank Traub in 1960. It is a wear-resistant seal material with unique properties unmatched in the industry. Turcon® seals are used in a variety of applications and serve numerous fields. “When I joined in ’86 the premier material we had to work with in terms of engineering applications was the Turcon® material,” says Tim Callison, President of Trelleborg Sealing Solutions Marketing Americas and a company employee since 1986. “Twenty-six years later, the premium material we have for applications today is Turcon®. It is a fantastic material with great breadth in its ability to provide solutions for our customers. It’s still regarded as the premier PTFE compounded material. It is still solving problems for us today, just as it did 26 years ago.” Currently, Trelleborg Sealing Solutions Great Lakes is based in Fort Wayne. The manufacturing facility is in the same location as the very first W.S. Shamban & Co. plant. The manufacturing plant is accompanied by the Hank A. Traub Technical Center, built in 1997, which serves as Trelleborg Sealing Solutions Americas headquarters and includes research and development labs. In 2010, Trelleborg opened its new Supply Chain Management Americas facility in Fort Wayne. Trelleborg Sealing Solutions plans to display an exhibit focusing on Turcon®’s history at the Allen County-Fort Wayne Historical Society later this year, as well as sponsor a speaker in January for the society’s free-speaker series. For more information about Turcon® visit www.turcon50.com. |

|

|

|

|

COMATROL

INTRODUCES PFD10-OD PROPORTIONAL FLOW DIVIDER COMATROL

INTRODUCES PFD10-OD PROPORTIONAL FLOW DIVIDERA new way to proportionally distribute flow between two hydraulic circuits Comatrol - a global leader in the design, manufacture and sale of engineered hydraulic cartridge valves and HICs - introduces the PFD10-OD Proportional Flow Divider for compensated flow sharing between two motors or hydraulic circuits. This circuit-saver solution takes the input flow and delivers precise flow management, providing engineers with a new tool for distributing flow on their applications. The PFD10-OD is an electro-proportional, compensated, normally open, flow dividing, pre-engineered HIC. When there is no current applied to the coils, the inlet flow is divided equally between the work ports A and B, with flows up to 40 LPM (10.7 GPM). The flow ratio between the 2 ports will proportionally vary as current is provided to the coils (from 0 to 40 LPM out each work port). The valve’s internal pressure compensation of both work ports provide the precise, repeatable and load-independent flow control to both work ports / circuits. Emanuele Vezzani, Comatrol Account Manager (Italy), shares, “We originally created this product for a unique customer application, building off our existing products and circuit expertise, and in the end came up with a design that we feel can find many homes with our customers. As we’ve shared this new compensated flow divider concept with customers, applications quickly come to mind where they could apply this pre-engineered solution.” When thinking of where to apply, think of dual circuits or motors that continuously require flow, and need to proportionally manage the amount of flow between them. Additionally, the built-in pressure compensator provides repeatable flow sharing performance, regardless of the loads on the circuits or motors. The PFD10-OD is a pre-engineered HIC that can be ordered using its nomenclature to specify options needed for the application, like coil voltage and termination, port sizes and seals. The aluminum manifold design is optimized for a small space claim on the vehicle, with 2 mounting holes provided as standard. The coils are designed for incorporation on machine control architecture that utilizes Sauer-Danfoss PLUS+1™ hardware. Adding PFD10-OD to your application using PLUS+1 GUIDE software is as easy as drag-and-drop. |

|

|

|

|

Sauer-Danfoss

Introduces DP600LX Series Mobile Machine Displays Sauer-Danfoss

Introduces DP600LX Series Mobile Machine DisplaysUpgraded PLUS+1TM compliant displays feature more powerful processor, new operating system, enhanced industry-leading viewability Sauer-Danfoss is pleased to introduce the new PLUS+1TM compliant DP600LX Series Mobile Machine Displays. Designed to meet the increasing demands of electronic system control and monitoring, the series provides mobile off-highway machine OEMs with next-generation color and monochrome graphical displays for both in-cab and open-air applications. The DP600LX, DP610LX and DP620LX displays feature a more powerful processor, a new operating system, enhanced industry-leading viewability and new features compared to previous models. “Demand for state-of-the art off-highway machine information displays continues to rise,” said Joseph P. Maher, Product Marketing Manager of Electronic Components at Sauer-Danfoss. “The advanced Sauer-Danfoss PLUS+1 compliant DP600LX Series Mobile Machine Displays provide rugged, high-performing, cost-efficient solutions that increase operator productivity — making them ideal for vehicle applications seeking differentiation. “The DP600LX Series offers not only a robust display platform for the future, but also backward compatibility for existing applications.” ‘New Engine Under the Hood’ Sauer-Danfoss DP600LX Series models are high-resolution, transflective thin film transistor (TFT) liquid crystal displays with eight soft keys and six buttons for navigation. Each display is user-programmable with PLUS+1 GUIDE (graphical user integrated development environment). Driving the new mobile machine displays is a new ARM-11 processor that provides greater responsiveness and faster screen data updates than its predecessor. Utilizing multimedia capability and 532MHz clock speed, the new processor performs 10 times faster. Graphics update two to three times faster and application execution is five to 10 times quicker. The new processor is capable of supporting higher screen resolution, offering the opportunity for future development. DP600LX Series displays run on a versatile LinuxTM operating system, the recognized industry standard for displays. Linux allows use of the screen editor in the Sauer-Danfoss GUIDE tool chain or an alternative screen editor. “The ARM-11 processor is like a new engine under the hood, powering the DP600LX Series displays to optimal performance,” Maher said. “The smooth new operating system serves as the transmission, helping the operator maximize the efficiency of electronic system control and monitoring.” The LCD, enclosure design, screen resolution and screen editor are similar to previous models, enabling backward compatibility. Industry-Leading Viewability Sauer-Danfoss has enhanced viewability that was already best-in-class, incorporating 15-bit true color and optional optically bonded LCD/lens technology into the DP600LX Series. Available with DP600LX and DP610LX models, optically bonded LCD/lens technology enhances clarity, increases sunlight visibility and prevents fogging by eliminating the air gap between the lens and the LCD module. “We took industry-leading viewability and made it even better,” Maher said. “The DP600LX Series displays feature sharper color that is clear and legible in sunlight and bright and powerful at night for maximum viewability.” |

|

|

|

|

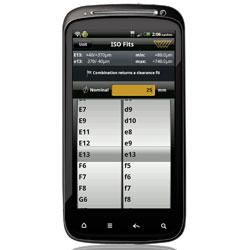

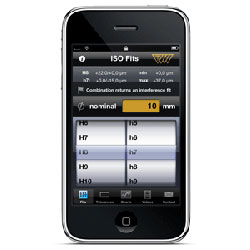

Trelleborg

Sealing Solutions Releases ‘ISO Fits & Tolerances’ for Android Trelleborg

Sealing Solutions Releases ‘ISO Fits & Tolerances’ for AndroidThe Trelleborg Sealing Solutions iPhone app “ISO Fits & Tolerances” has exceeded 15,000 downloads since its launch and is now released for use with Android phones. Providing results based on the ISO 286 System of Limits and Fits, this app is aimed at engineers with the goal of helping them save time and enabling them to work away from their desks. “ISO Fits & Tolerances” is intuitive and very easy to use. Upon entering the nominal diameter needed, users simply select the tolerance classes for bore and shaft. The app then provides the complete ISO fits definition with all relevant values, including the type of fit. Tolerances are shown for the most commonly used ISO tolerance classes, and convenient graphs illustrate these classes by bore and shaft. “This was the first app from Trelleborg Sealing Solutions, and from feedback and downloads we know it is much appreciated by users,” says Project Manager Web and Mobile for Trelleborg Sealing Solutions, Wolfgang Heinrich. “We are always looking for ways to make our customers’ working lives easier, and with the workforce becoming more mobile every day, we need to provide tools that can be used on the go. “Since the launch of the original version, there has been much demand for an Android- compatible app. We’re pleased that we have been able to satisfy our users’ needs.” Also included with the app is one-touch access to the automatically updated library of Trelleborg Sealing Solutions films and animations on YouTube. For more information, just click “Contact” and you can choose to email or be connected to the Trelleborg Sealing Solutions website. Although the app was originally developed for sealing applications, it can be used in a wide range of design situations, whether related to sealing or not. “ISO Fits & Tolerances” is available in English and German free of charge on Google Play. It can easily be found by searching for “Trelleborg ISO Fits.” |

|

|

|

|

MICROMATIC

RELEASES NEW CUSTOM SERIES 10,000 RPM ROTATING ACTUATOR MICROMATIC

RELEASES NEW CUSTOM SERIES 10,000 RPM ROTATING ACTUATORUntil now, our actuators have been limited to 5000 rpm in our standard line of rotating actuators. But with advancements in technology we are now providing units for applications of 10,000 rpm and beyond. What is a rotating actuator? Its interior design and construction are similar to standard lines of stationary actuators, but the rotating actuator, unlike the stationary models, revolves in application. Also, its applications are entirely different. It consists of an aluminum alloy body with a precision machined cylindrical chamber, a central splined end shaft on which vanes are fixed. Power is derived from either hydraulic or pneumatic pressure directed against the vanes which, in turn, rotate the splined shaft. This type of actuator maybe referred to as a “Spinner.” The entire actuator rotates or spins with the drive mechanism being tested. The drive mechanism might be the transmission of a military helicopter. Some helicopters have two GE T700 turbo shaft engines each producing up to 2000 hp, each engine is joined together through a sophisticated drive mechanism that powers the two rotors allowing agile maneuvering. It is this sophisticated drive mechanism that needs testing. That’s where our Micromatic rotating actuator is used. There are several test stands that take the drive mechanism through its paces. Each test stand has a rotating actuator installed that imparts a calculated amount of additional torque or load on the system. This ensures that the drive mechanism is ready to be used in production. Our Website: http://www.micromaticllc.com/ |

|

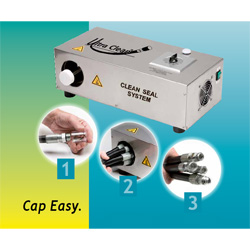

The

New Clean Seal Flange from Ultra Clean The

New Clean Seal Flange from Ultra CleanFor many years now, the hydraulic industry has been challenged with keeping systems contamination free. When components such as pumps, cylinders or valves are removed from the hydraulic system, the oil is then open to contaminants. Other Issues occur when attachments are added or removed from construction equipment, such as hydraulic breakers, grapples, shears, etc...thus leaving the oil susceptible to dirt and contaminants, while also risking the environment to oil spills. Hence the Clean Seal Flange was born! An innovative tool, to simply and quickly keep oil in and dirt out! Color coded for quick identification. Universal fitment for sizes -8 to -32 flanges. Designed to withstand thermal expansion pressures. •Keeps oil in, and dirt out! •Seal hydraulic flanges fast & easy •Durable anodized aluminum construction •Easy on/off, no tools required! •Eliminates flange capping hassles •No drips, leaks or spills •Ensures cleanliness Ultra Clean 746 Shiloh Pike, Bridgeton, NJ 08302 U.S.A. Phone: 856-451-2176 Fax: 856-453-4975 800-791-9111 |

|

|

|

|

Valves

with Integral Position Sensing Valves

with Integral Position SensingHydraForce has released valves with an integral sensing option capable of transmitting an on or off signal. These valves are designed with parts commonality in mind which allows these sensing options to be easily applied to numerous valves, and keeps the sensing option cost-effective. This new sensing solution was designed for interchangeable use with any existing HydraForce cartridge valve, is compatible with manual override options, and uses an industry standard cavity. The innovative sensing option design consists of assembling a common solenoid valve pole tube and hydraulic valve assembly on the opposite ends of a coupling tube, which contains an elongated plunger. The new coupling tube, sensor and sensor housing are designed such that they are usable in valves of different types and sizes ranging from 10 to 16 sizes. These new components are connected to Hall Effect sensor element which monitors and transmits the appropriate voltage signal when the valve is actuated or in the neutral position. The sensing element chosen was a Hall Effect sensor which is known for its proven reliability in the field. HYDRAFORCE INC 500 Barclay Blvd. Lincolnshire, IL 60069 USA Phone: 847 793 2300 Fax: 847 793 0086 |

|

|

|

|

Sauer-Danfoss

Launches Innovative JS7000 Joystick Sauer-Danfoss

Launches Innovative JS7000 JoystickMobile off-highway machine control solution sets new standards for performance, durability, flexibility and operator comfort The new Sauer-Danfoss JS7000 joystick offers an unparalleled machine control solution to OEMs of mobile off-highway equipment worldwide. Designed from scratch after exhaustive research on operator needs, the JS7000 joystick establishes new industry standards for performance, durability, flexibility and end-user comfort. The PLUS+1TM Compliant JS7000 is well-suited for off-highway machines including backhoe loaders, skid steer loaders, telehandlers, wheel loaders and dozers. “Today’s OEMs are placing increased value on human-machine interface (HMI) components to improve machine performance and safety, operator efficiency and comfort as well as brand image,” said Joseph P. Maher, Product Marketing Manager for Sauer-Danfoss. “The innovative JS7000 joystick provides them with a game-changing solution, meeting a complete range of customer and application requirements in harsh off-highway conditions.” Extensive Research Drives Development Prior to designing and developing the JS7000, Sauer-Danfoss undertook extensive ethnographic research to identify the diverse needs of off-highway machine operators. Research methodology included not only conducting in-person interviews but also recording in-cab video of end users performing typical tasks in actual jobsite environments. “The research was exceedingly thorough and gave us singular insight into the unique needs of off-highway machine operators,” Maher said. “Combining the research findings with our previous application experience and the industrial design expertise of partner Brooks Stevens, we developed a world-class joystick that the industry didn’t realize it needed.” “We have rigorously tested this product as well as leading competitive products, putting millions of cycles of harsh treatment on multiple samples of both. Customers afforded sneak previews of the product have voiced their approval and informed us that we have done our homework well.” Robust, Durable and Flexible Design The JS7000 features a robust and intuitive design, enabling the joystick to deliver industry-leading performance, durability, flexibility and operator comfort for the life of its off-highway machine. Featuring a 300-pound shaft load and a minimum ingress protection rating of IP 67 — meaning the joystick is dust-tight and protected against temporary immersion in water — the JS7000 can withstand the most rugged operation styles and challenging work environments. The joystick is designed to facilitate efficient maintenance and repair, providing a significant long-term advantage in total cost of ownership. The JS7000 also offers unsurpassed flexibility to meet various customer and application requirements. Multiple options can be specified into the JS7000’s physical configuration, and the joystick’s modular design allows for timely configurability. The JS7000 is available with single- and dual-axis configurations and spring centering, with the option of 20 or 25 degrees of handle travel in the dual-axis configuration. Ergonomic left-hand and right-hand vertical grip design options enable comfortable and efficient operation. Various pushbutton, trigger switch and proportional roller switch configurations are available on each grip. The JS7000 has analog and CAN (Controller Area Network) electrical output options, and can support J1939 and CANopen communication protocols. Part of the flexible, powerful, expandable and growing PLUS+1TM family of mobile machine management products, the JS7000 integrates seamlessly with other Sauer-Danfoss PLUS+1 products. This synergy among components enables accelerated mobile machinery development and ultimately maximizes machine productivity and operator comfort via a smooth, highly responsive control system. The JS7000’s electronics are designed to facilitate compliance with functional safety standards. The joystick includes redundant hall effect sensors and EMC immunity to 150 V/m while supporting SIL2 (Safety Integrity Level 2) certifiable systems. “The JS7000 joystick reaches new levels of performance, efficiency, durability and flexibility, and will become the new market reference for ergonomic and aesthetic design,” Maher said. “By choosing a partner with expertise in HMI, OEMs can speed up system development, reduce total installed costs, minimize time to market and ultimately influence end-user support of equipment selection.” More details online at www.sauer-danfoss.com. |

|

Simrit’s

Nanotechnology Surface Process Improves Seal Longevity, Abrasion

Resistance Simrit’s

Nanotechnology Surface Process Improves Seal Longevity, Abrasion

ResistanceTo better meet customer needs for more robust seals, Simrit has developed an advanced surface treatment process to improve seal function and service life. Simrit’s Reduced Friction by Nanotechnology (RFN) method is one of the newest tools available for enhancing seal performance. Sealing components made of elastomeric materials have inherently high surface energies (tackiness) and a high coefficient of friction (COF). Therefore, when an elastomeric seal makes contact with the mating component, the interface of the two surfaces can produce a “stiction” effect, which is detrimental when the contact is intermittent. For example, stiction has a significant impact on applications like bicycle shock absorbers, which need to have a low breakaway force for smooth shock function. To prevent stiction, Simrit created the RFN process, which consists of applying its proprietary surface modification to rubber components to reduce COF. The transformed surface offers high abrasion resistance, low COF, resistance to aggressive fluids and improved long-term service. The RFN treatment is odorless, translucent in color and compatible with applications that require purity. Applications that require low stiction and long service life, such as valve sealing components and diaphragms, can greatly benefit from Simrit’s RFN treatment. “With nearly 100 years of sealing experience, developing technologies and processes that provide increased consistency and reliability for our customers is a top priority for Simrit,” said David R. Monaco, president, Simrit. “Our pioneering RFN surface treatment has the ability to dramatically improve the longevity and function of elastomeric seals in a variety of applications, including designs that operate in extreme conditions.” RFN treated surfaces have consistently shown a 70 percent reduction in static COF, aggressive media resistance and lower torque and loading properties. Additionally, long-term exposure to fuel, ozone and wear have shown no increase in COF in treated surfaces, while non-treated surfaces exhibit an 80 to 100 percent increase in COF over time. Further, the RFN process doesn’t alter the physical properties of the elastomer and enables the seal to remain flexible to withstand extremely low temperatures, as well as high forces, without cracking. Simrit is part of the Freudenberg and NOK Group Companies, which have total annual sales of more than $7 billion. The global Freudenberg and NOK Group offers an extensive portfolio of precision-manufactured products for the aerospace, appliance, automotive, marine, medical, off-highway equipment, recreational vehicle and renewable energy markets. For more information, visit the Simrit website at www.simrit.com. |

|

|

|

|

The

Liquid Wrench Powered by EnviroLogic line features Penetrating

Oil, Jack Oil, Aerial Lift Fluid, and Mobile Equipment Hydraulic

Fluid. The

Liquid Wrench Powered by EnviroLogic line features Penetrating

Oil, Jack Oil, Aerial Lift Fluid, and Mobile Equipment Hydraulic

Fluid.These new, non-hazardous formulas are the company’s first products to market since launching in 2010 as a biobased platform of Radiator Specialty Company (RSC), the 86-year-old company that houses the Liquid Wrench® and Gunk® brands under its RSC Chemical Solutions division. “RSC Bio Solutions is committed to producing biobased cleaners, degreasers and lubricants that provide non-hazardous alternatives for applications where both high performance and safety are essential,” said Mike Guggenheimer, Vice President of Business Development for RSC Bio Solutions. “These new products increase safety and efficiency for our customers because if there is an accidental spill in the workplace, no harm will be done to their employees or to the environment.” The new product line was created through RSC Bio Solutions’ partnerships with Gemtek® Products LLC and Terresolve™ Technologies Ltd., two leaders in the biobased market. RSC Bio Solutions’ premiere products include: Jack Oil The Liquid Wrench® Powered by EnviroLogic® Jack Oil provides high antiwear and corrosion protection, and is formulated to reduce sling off, which offers superior lubrication. The biobased ISO 46 grade jack fluid meets all requirements of major hydraulic jack OEMs and component suppliers, and delivers premium performance when compared to petroleum-based jack oils. The Jack Oil is available in 1-gallon, 5-gallon, and 55-gallon containers. Aerial Lift Fluid The Liquid Wrench® Powered by EnviroLogic® Aerial Lift Fluid offers a premium performance when compared to petroleum-based aerial lift fluids. The formula is readily biodegradable and safe for use in all aerial lift hydraulic systems. The non-hazardous technology is designed to meet or exceed the requirements of most major hydraulic equipment manufacturers and has outstanding performance in low temperature environments. The Aerial Lift Fluid is available in 1-gallon, 5-gallon, and 55-gallon containers. Mobile Equipment Hydraulic Fluid The Liquid Wrench® Powered by EnviroLogic® Mobile Equipment Hydraulic Fluid is readily biodegradable and safe for use in all ISO 46 grade hydraulic systems. This biobased hydraulic fluid is designed to meet or exceed the requirements of most major hydraulic equipment manufacturers and has outstanding performance in low temperature environments. The Mobile Equipment Hydraulic Fluid is available in 1-gallon and 5-gallon containers. For more information or to purchase these products, please visit: www.rscbio.com. |

|

|

|

|

Brennan

Industries Introduces New Brennan Black® Coating For the Most

Advanced Protection Against Red Rust Corrosion Brennan

Industries Introduces New Brennan Black® Coating For the Most

Advanced Protection Against Red Rust CorrosionBrennan Industries Inc., a leading international supplier of hydraulic fittings and adapters, has introduced its new Brennan Black® coating, the most advanced protection against rust and corrosion. This proprietary Bi-LENE® coating is a blend of fluoropolymer, engineered plastics and selected corrosion inhibitors that is tailored to provide specific properties for particular applications unlike conventional fluoropolymer coatings. The properties consist of low friction, strong adhesion, resistance to wear and abrasion, excellent resistant to corrosion, chipping and elements such as weather, sunlight and salt water. Field and lab tests show the coating resists corrosion past 1,600 hours of exposure making it at least 300 percent more resistant to corrosion than competitor’s advanced plating. It works in a wide range of temperatures from negative 420 degrees Fahrenheit to 500 degrees Fahrenheit. “The Brennan Black coating is the most advanced corrosion resistant coating available,” said David M. Carr, president, Brennan Industries. “The Brennan Black coating offers the highest industry standard and is the answer for protecting systems and ensuring longevity in the most corrosive and harsh environments enabling customers to save money by protecting operations and reducing replacement costs.” The Brennan Black coating is best demonstrated on steel hydraulic adapters, where it provides unparalleled performance in resistance to corrosion. The Brennan Black coating is also available throughout five additional Brennan Industries product classes. Test results are available upon request. For more information, contact: Brennan Industries Inc., 6701 Cochran Road, Cleveland, OH 44139. Phone: (440) 248-1880. Toll-free: (888) 331-1523. Fax: (440) 248-7282. E-mail: sales@brennaninc.com. www.brennaninc.com. |

|

|

|

|

Eaton

Introduces Next Generation Proportional Directional Valves

Designed To Support Sophisticated Electro-hydraulic Axis

Controls Eaton

Introduces Next Generation Proportional Directional Valves

Designed To Support Sophisticated Electro-hydraulic Axis

ControlsEDEN PRAIRIE, Minn. … Diversified industrial manufacturer Eaton Corporation today announced the introduction of its line of next generation proportional directional valves designed to provide integrated programmable control capabilities in sophisticated electro-hydraulic applications. Eaton’s new KBS series valves are designed to support both centralized and distributed axis control architectures in high-performance applications including test simulation, blow molding, wind turbine control, metal forming, pulp and paper machinery, and primary metals production. Eaton’s KBS series valves feature programmable onboard electronics and integral spool Linear Voltage Differential Transformer (LVDT) sensors to provide precise, accurate, responsive axis control capabilities. The initial products are offered in ISO-3 and ISO-5 sizes with rated flows of 40 LPM and 100 LPM (10.6 and 26.4 gpm), and maximum flows of 75 lpm and 180 lpm (19.8 and 47.6 gpm) respectively. Dynamic bandwidth for the ISO-3 valves is 150 Hz and 100Hz for the larger ISO-5 models. Both have 350 Bar (5,075 psi) rated A- and B-ports and 250 Bar (3,625 psi) rated T-ports. “These valves represent the next generation of electro-hydraulic sophistication,” said Colin Cooper, product manager, industrial controls. “They provide four levels of control capability in a modular design, from an entry level valve that is quick and easy to configure, right through to a valve that can be uniquely customized by uploading application code created using Eaton Control F(x) software based on the IEC-61131-3 programming standard. Additionally the valves can be selected with CanOpen field bus communication and control capability, a range of optional sensor inputs, along with embedded on-board sensor capability and easy-to-read LED status indicators. “We have optimized the KBS series valves for performance, flexibility, reliability and easy diagnostics. These valves offer customers truly differentiated machine and application performance benefits which translate into significant improvements in efficiency, productivity and repeatability for numerous industrial applications,” Cooper added. “Additionally, they also have best-in-class IP65 and IP67 protection against dirt and moisture ingression, and best-in-class 85? C ambient temperature ratings.” The KBS Valve specifications, pricing and lead times will be available through Eaton and its global channel partners. Eaton’s Hydraulics Group is a segment of the company’s Industrial Sector. The business is a worldwide leader in the design, manufacture and marketing of a comprehensive line of reliable, high-efficiency hydraulic systems and components for use in mobile and stationary applications. Mobile and stationary markets include agriculture, alternative energy, construction, forestry, manufacturing, material handling, mining, oil and gas, processing, transportation and utility equipment. Eaton’s Hydraulics Group provides customer-driven solutions under product names such as Aeroquip®, Boston®, Char-Lynn®, Eaton®, Hydrokraft®, Hydrowa®, Hydro-Line®, Integrated Hydraulics®, Synflex®, Vickers®, Walterscheid™, and Weatherhead®. For more information, visit www.eaton.com/hydraulics. Eaton Corporation is a diversified power management company with 2010 sales of $13.7 billion. Celebrating its 100th anniversary in 2011, Eaton is a global technology leader in electrical components and systems for power quality, distribution and control; hydraulics components, systems and services for industrial and mobile equipment; aerospace fuel, hydraulics and pneumatic systems for commercial and military use; and truck and automotive drivetrain and powertrain systems for performance, fuel economy and safety. Eaton has approximately 70,000 employees and sells products to customers in more than 150 countries. For more information, visit www.eaton.com. |

|

|

|

|

Comatrol

introduces EasyValve 2.0 Comatrol

introduces EasyValve 2.0Comatrol has invested in expert tools to streamline the design process, lowering turn around time and improving product specification quality. Comatrol’s suite of HIC design and prototyping tools, including our free design software EasyValve™, takes custom hydraulic integrated control solutions to the next level, allowing you to get involved at the very beginning of the design stage all the way through to installation. The intuitive user interface of EasyValve™ allows the engineer to efficiently create hydraulic circuit schematics by simply dragging and dropping from Comatrol’s complete digital library of cartridge valves, Cetop valves and accessories. Engineers can capture their technical, commercial and application requirements to accurately document and communicate their custom HIC needs allowing them to get exactly what they want from the first drawing, reducing the prototype cycle time by 50 percent. About Comatrol Comatrol, a member of the Sauer‐Danfoss (NYSE: SHS) Group, is the most responsive source for Cartridge Valves and Hydraulic Integrated Circuit (HIC) solution needs. Comatrol works with customers and suppliers around the world to manufacture high performance machine control solutions for mobile, on‐highway, energy and industrial equipment markets. Additional information is available at www.comatrol.com or follow us on Facebook™ at www.facebook.com/comatrol. |

|

|

|

|

Simrit

Revolutionizes Surface Finish Testing Methodology to Increase

Seal Performance Simrit

Revolutionizes Surface Finish Testing Methodology to Increase

Seal PerformanceNewly identified parameters more accurately assess rod surface finish of tribological systems To improve and minimize variation of rod counter surface quality for hydraulic applications, Simrit has specified six additional parameters. Expanding on the three parameters that are traditionally used to measure surface finish and define sealing technology requirements, these new attributes allow engineers to more accurately predict, and therefore anticipate, seal behavior without additional measurements or time. “The precise evaluation of an application’s surface finish is critical to the overall effectiveness of the entire sealing system,” said Joel Johnson, vice president of technology, Simrit. “Based on the Abbott Firestone Curve and ISO methodology, our new factors modernize the standards for counter surface examination, which helps extend the life and increase the performance of sealing systems.” Simrit determined that, while important, the traditional three testing parameters – Ra, Rmax and Rz – were not adequate to accurately classify surface abrasiveness and a component’s potential to hold lubricant. To address current and future industry trends and expectations, Simrit developed an improved methodology that better identifies surface characteristics over a defined length and complete depth of the profile. Initial in-house testing by Simrit indicates that the new parameters, through the more accurate evaluation of surface characteristics, are able to reduce part wear and extend system life. Additionally, Simrit’s newly identified methodology can be applied to numerous markets and dynamic applications. For more information, visit the Simrit website at www.simrit.com |

|

|

|

|

Eaton

Announces Breakthrough in Hydraulic Hose Technology - The Hose

That Knows Eaton

Announces Breakthrough in Hydraulic Hose Technology - The Hose

That KnowsLifeSense™ Hose Launched at IFPE/ConExpo EDEN PRAIRIE, Minn. … Diversified industrial manufacturer Eaton Corporation today announced the launch of a new breakthrough technology that enables reporting of imminent hose assembly failure by means of real-time monitoring of high pressure hose assemblies used in hydraulic systems. Eaton’s LifeSense™ hose, a patented hydraulic hose condition monitoring system, will be introduced to the North American market at the International Fluid Power Exposition (held in conjunction with Conexpo 2011) in Las Vegas, March 22 - 26, and to the European market at Hannover Messe 2011 in Hannover, Germany, April 4 - 8. Eaton’s LifeSense hose was developed in conjunction with Purdue University and the Purdue Research Foundation's Office of Technology Commercialization to continuously monitor the health of hydraulic hose assemblies and alert users when an assembly approaches the end of its useful life. The LifeSense hose can monitor and track the health of each hose assembly in a hydraulic system. This system does not estimate or predict through arithmetic calculations when a hose is going to fail, like some products on the market today. The LifeSense hose actually detects when a hose is nearing the end of its useful life. Then an alert is sent to the user so that the assembly can be replaced to prevent downtime. A single monitoring unit can handle input from multiple hose assemblies. “Most hydraulic maintenance programs are designed to avoid hose failures by replacing assemblies at regular intervals, using a schedule based on usage data or past experience,” said Doug Jahnke, Eaton product marketing manager. “As a result, a large number of perfectly good hydraulic hose assemblies are discarded long before the end of their useful life out of fear that they might fail. The LifeSense hose allows the user to utilize virtually all of the useful life of a hydraulic hose assembly, more than 50 percent longer life in a typical lab test, thus saving on replacement costs and associated downtime while providing peace-of-mind that productivity will not be impeded and safety not compromised by unpredicted hose failure.“Additionally, hydraulic hose failure is one of the largest causes of unplanned maintenance events,” Jahnke said. “Hose failures in the field present serious safety issues, environmental concerns and result in unscheduled system downtime, all of which have serious economic impacts. The initial LifeSense hose offering will include the widely-used -8, -12 and -16 two-wire hose assemblies. Eaton’s LifeSense hydraulic hose condition monitoring offers performance equal to industry standard 2SN pressure-rated hose and is certified to the same industry specifications as conventional hydraulic hose products. The technology is currently available for trial with factory-made assemblies including straight JIC swivel fittings. Eaton’s Hydraulics Group is a segment of the company’s Industrial Sector. The business is a worldwide leader in the design, manufacture and marketing of a comprehensive line of reliable, high-efficiency hydraulic systems and components for use in mobile and stationary applications. Mobile and stationary markets include agriculture, alternative energy, construction, forestry, manufacturing, material handling, mining, oil and gas, processing, transportation and utility equipment. Eaton’s Hydraulics Group provides customer-driven solutions under product names such as Aeroquip®, Boston®, Char-Lynn®, Eaton®, Hydrokraft®, Hydrowa®, Hydro-Line®, Integrated Hydraulics®, Synflex®, Vickers®, Walterscheid™, and Weatherhead®. For more information, visit www.eaton.com/hydraulics |

|

|

|

|

Gates

easy-to-bend MegaSys hoses reduce costs, downtime Gates

easy-to-bend MegaSys hoses reduce costs, downtimeGates Corporation has expanded and re-engineered its MegaSys® product line to now include nine constant-pressure hydraulic hoses that have the smallest bend radius of any SAE-equivalent hose in the industry. The Gates spiral-wire and wire-braid hoses can be bent up to one-third the SAE specification, thereby saving overall hose assembly length and cost by as much as 64 percent. This flexibility also means that Gates MegaSys hoses are easier to handle, and can be routed in tighter spaces during installation, thus reducing downtime. Two leak-free fitting designs are available: Gates MegaCrimp® couplings for one- and two-wire braid hydraulic hoses, and GlobalSpiral™ couplings for all Gates MegaSys four- and six-spiral wire hoses up to 8,000 psi. Corrosion-resistant TuffCoat™ plating comes standard. Gates MegaSys hoses are also available with either MegaTuff® or XtraTuff™ hose covers that outperform all other standard abrasion-resistant hose materials on the market today. Special engineering provides up to 300 times the abrasion resistance of rubber hose covers. To make the nine MegaSys hoses easier to identify in stock or in service, each features a distinctive, color-coded layline that indicates the hose trade name, size and pressure rating, SAE, EN or DIN standard, and MSHA flame-resistance compliance. For additional information, go to gates.com/megasys. |

|

|

|

|

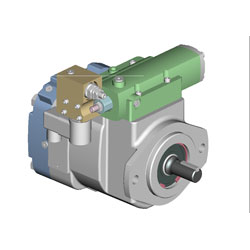

Parker

Announces New PV360 Axial Piston Pump; Smartly Designed, Quiet,

Modular and Easy-to-Service Pump Aims to Increase the

Productivity of Parker

Announces New PV360 Axial Piston Pump; Smartly Designed, Quiet,

Modular and Easy-to-Service Pump Aims to Increase the

Productivity of Heavy-Duty Machines Parker Hannifin Corporation, the global leader in motion and control technologies, has introduced a new addition to the PVplus axial piston pump family, the PV360. A variable displacement, 360 cc/rev pump, the PV360 addresses a wide range of heavy-duty mobile and industrial applications with operating pressures up to 5,000 psi (350 bar). Featuring a large servo piston for exceptionally fast response, the PV360 is best suited for cranes and lifting equipment, presses, metal forming machines, hydraulic power units (HPUs) and marine use. In these applications, where the hydraulic system may already be subject to high impact forces, the PV360 – thanks to Parker’s patented ripple chamber technology – produces between 40 and 60 percent less pressure and flow pulsation than comparable pumps. This means that fewer sine waves – capable of loosening hydraulic connections and damaging downstream components – are introduced into the system as added burden; pump noise is also subdued. A second key advantage of the PV360 is its modular design. A wide variety of compensator options are offered including standard pressure, remote pressure, load sensing and horsepower. Pilot valves can also be directly mounted without any piping. This permits simple and straightforward in-field conversion, when necessary. The ease of service afforded by the PV360 is furthermore of great benefit. Metric and SAE mounting interfaces are available and threads/ports can be ordered metric or UNC/UNF, meaning connectors and mounting bolts – even for body and compensator – are available according to local standards around the world. For installation and maintenance, no special tools are needed to alter the pump's configuration, meaning part supply – and once again, field service – present little issue. Finally, all Parker PVplus pumps are 100 percent through-drive capable and are equipped with an easily accessible displacement adjustment screw. In double configurations, both pumps can be used at full flow and nominal pressure at the same time. Therefore, multiple pump systems can be built with only one drive motor and the maximum displacement of any PVplus pump – also in pump combinations – can be adjusted or modified at any time. In addition to the new PV360, Parker’s PVplus pump series includes 16, 20, 23, 28, 32, 40, 46, 63, 80, 92, 140, 180 and 270cc displacement models. To learn more, visit www.PHpump.com, email pumptechsupport@parker.com or call the Hydraulic Pump Division at 937.644.3915. |

|

|

|

|

Gates

hydraulic hose apps optimize performance, minimize downtime Gates

hydraulic hose apps optimize performance, minimize downtimeTwo, new Gates hydraulic apps optimize system performance and minimize downtime by monitoring hose service life, and identifying replacement hose specifications. Gates Sentry IQ Service is a predictive maintenance app that monitors pressure and temperature of a hydraulic assembly to gauge remaining hose life. The app is designed for equipment and processes in applications where unexpected hose failures can cause expensive downtime, compromise safety, and require costly repair and clean-up. Gates Sentry™ IQ Service is suited for both new equipment designs and aftermarket oil production applications. Gates other proactive maintenance app, Sentry ID Service, is a high-radio frequency tagging system that identifies and tracks specific hydraulic hose assemblies operating worldwide. Gates Sentry ID Service allows maintenance technicians to electronically read and identify hose assembly specifications including hose type, size, length, end fittings and orientation. A replacement hose can easily be fabricated at the installation or ordered from a Gates distributor, thereby minimizing downtime of the oil production equipment. For information, go to www.gates.com/sentry. |

|

|

|

|

MTS

SENSORS INTRODUCES NEW SENSOR FOR HYDRAULIC CYLINDERS USED IN

STEERING OFF- ROAD EQUIPMENT MTS

SENSORS INTRODUCES NEW SENSOR FOR HYDRAULIC CYLINDERS USED IN

STEERING OFF- ROAD EQUIPMENTCARY, N.C. - MTS has extended its product portfolio of magnetostrictive position sensors for mobile hydraulics with the new Temposonics® Model MB stainless steel sensor. The unit has been developed specially for external attachment to a hydraulic cylinder, and can be used in applications such as steer-by-wire. With its compact dimension and an M14 x 1.5 thread, the sensor is suitable for mounting on double-acting steering cylinders. The magnet is integrated into the piston and transmits the position through a non-ferrous cylinder wall to the sensor. By using two externally mounted sensors, they can function in a redundant capacity to meet stringent safety requirements. Apart from easy external mounting on the double rod cylinder, the Model MB sensor is also suitable for direct thread-in installation in differential cylinders. In this type of installation, a ring magnet mounted on the piston slides over the sensor rod and marks the position. Thus, the Model MB sensor offers the flexibility to either thread the sensor into the cylinder, or to attach it on the outside. Additional M-Series sensor models are available that allow the sensor to be embedded in the hydraulic cylinder, permitting complete cylinder integration. The Temposonics® MB position sensor is available with 12 V supply for a measuring range of 72 - 250 mm and designed for large-scale integration in the mobile hydraulics industry. Its compact size makes it easy to install and the sensor’s absolute, non-contact position measurement ensures a long service life. By utilizing a direct, analog voltage output, the sensor is able to provide a high-accuracy position feedback with a linearity and hysteresis of < ± 0.25 mm and a resolution of 0.25 mm. The sensor also has a high-survivability rating with a 100 g single shock rating, as well as a vibration profile that meets the ISO 16750-3 specification. Furthermore, the protection type IP 69K ensures that the electrical connection is absolutely dust and watertight. For more information on MTS Sensors, please contact: Hub vom Berg, MTS Sensors Division, 3001 Sheldon Drive, Cary, NC 27513. Phone: (919) 677-2370. E-mail hub.vomberg@mts.com or visit http://www.mtssensors.com. MTS Sensors, a division of MTS Systems Corp., is the global leader in the development and production of magnetostrictive linear-position and liquid-level sensors. The Sensors Division is continually developing new ways to apply magnetostrictive sensing technology to solve critical applications in a variety of markets around the world. With facilities in the U.S., Germany, Japan and China, MTS Sensors Division is an ISO 9001 certified supplier committed to providing worldwide innovative sensing solutions. |

|

|

|

|

Manuli

Q-Safe offers a wide range of hydraulic couplings that meet and

exceed the industry standards for double shut-off applications. Manuli

Q-Safe offers a wide range of hydraulic couplings that meet and

exceed the industry standards for double shut-off applications.

The Q-Safe products are manufactured to many of the industry standards such as ISO 7241-A, ISO-B,ISO 16028, ISO 15171-1, ISO 5676 and ISO 7241-2. Manuli Q-Safe range offers hydraulic solutions for markets such as Construction, Agriculture, Forestry, Mining, Utility Vehicles, Transportation and general Industrial. Product ranges from ¼” to 1½” Body sizes and up to 10,150 psi working pressures and 1,000,000 impulse cycles. All series are provided with an environmental friendly Cr3+ (Trivalent Chrome) surface coating for an excellent resistance to corrosion, exceeding the ISO 4520 requirements (salt spray resistance: 240 hours for white corrosion and 400 hours for red corrosion). Manuli also offers a range of Check Valves, caps/plugs and replacement spare parts. All Q-Safe products are 100% visually, functionally and air sealing tested and available in our Warrendale, PA facility. Manuli Hydraulics Warrendale,PA Phone: 724-778-3380 Fax: 724-778-3381 |

|

|

|

|

Meet

FPTI’s newest innovation...the MF500-HT Hydrostatic Transmission

Training Simulator Meet

FPTI’s newest innovation...the MF500-HT Hydrostatic Transmission

Training SimulatorMAIN FEATURES: • Learn any type of transmission system – Can be configured to teach any type of hydrostatic transmission, e.g., Sauer-Danfoss, Sundstrand, Rexroth, Eaton, Dennison, Linde, etc. • Standard unit equipped with the two most popular pumps in the industry – Piggy-backed pumps are Rexroth A4V and Sauer-Danfoss M46 – The two most popular pumps in the skid-steer and agricultural industries. • Electronic joystick controllers – Each pump is equipped with its own electronic displacement control joystick. • State-of-the-art electronics – Pumps feature electronic displacement control. • Dual wheel motors – Different types to increase learning capability - high torque/low speed with integral spring-applied/ hydraulic release brake and axial piston with integral hot-oil shuttle valve. Wheel motors can be connected in parallel or series to replicate any type of design configuration. • Panel PC with 19” color touch-screen – Features simulator activities and comprehensive diagnostics programming. Telephone: (801) 908-5456 FAX: (801) 908-5734 P.O. Box 711201, S.L.C., Utah 84171 Web: www.fpti.org e-mail: info@fpti.org |

|

|

|

|

Flo-tech

PFM testers now offer internal pressure relief discs Flo-tech

PFM testers now offer internal pressure relief discsFebruary 1, 2011 - The rugged PFM Tester Series by Flo-tech now features an internal safety pressure relief disc, or “burst disc”. The PFM series has long been relied upon to measure flow, pressure, temperature and horsepower on mobile hydraulic equipment. Effective immediately, all PFM Testers will include an internal burst disc component. The new design ensures that in the event of an over pressurization, that the fluid is safely allowed to bypass the load valve and remain within the hydraulic system. No fluids will escape outside of the tester. Maintenance costs are thereby reduced, and potential harm to the environment from spills is eliminated with the internal design. As before, the internal burst disc is field-replaceable, should an over pressurization occur. The PFM Tester utilizes a turbine rotor and a magnetic pick-up to measure flow rates by measuring the frequency pulse output from the rotor. Volumetric flow rate is displayed on an LCD or sent via digital output to a PC. The PFM Series provides reliable readings with an accuracy of 1% of full scale and a repeatability of 0.2%. Temperature is measured via internal sensor, and pressure is measured via analog gauge or high-sensitivity digital sensor. For ease of use and safety, all testers have loading valves with fingertip control and pressure surge protection. About Flo-tech™ Flo-tech is part of Racine Flow Meter Group and is a leading manufacturer of portable testers and turbine flow meters for hydraulic fluids. Racine Flow Meter Group is part of Racine Federated Inc., a private corporation celebrating 40 years of continuous operation in Racine, Wis., USA. Racine Flow Meter Group manufactures turbine, variable area, hydraulic testing, differential pressure, vortex shedding and ultrasonic flow measurement products. Brand names include Blancett, Dynasonics, Flo-tech, Hedland, Preso and Racine Vortex. The Racine Flow Meter Group serves industrial, oil & gas, municipal, irrigation and energy management markets worldwide. Flo-tech, Racine Flow Meter Group 8635 Washington Avenue Racine, WI 53406-3738 USA 262-639-6770 www.racinefed.com/flow |

|

|

|

|

|

Convert Hydraulic Input To Air Pressure Output NORTH MANKATO, Minn. — MICO, Incorporated is introducing its hydraulic-over-air relay valves at the IFPE/ConExpo show in Las Vegas in booth #13653. The valves are designed to convert hydraulic modulated input pressure to a proportional output air pressure. The new relay valves are ideal for various on- and off-highway applications, such as controlling an air-braked trailer with a hydraulically braked towing vehicle that has an air power source. The system originates with a hydraulic vehicle component, such as a master cylinder or hydraulic control valve, which delivers a given hydraulic input pressure. This input pressure sends a pilot signal to the relay valve in order to modulate air brake pressure on the other end. MICO offers three different hydraulic-over-air relay valve designs: single, dual and tandem. The single input design provides one hydraulic pilot port to control modulated air braking pressure. The dual input features two independent ports, either of which can accept pilot pressure. When pressure is applied to both ports simultaneously, the controlled air braking pressure ratio increases proportionally. The dual input ports can be set up for different pressure ratios, making the dual design a good fit for certain steering assist applications. Functionally similar to the single design, the tandem input provides redundancy by utilizing two independent pilot pressure ports. This enables hydraulic pilot pressure to be applied to either port while allowing the pressure ratio to remain the same. The new relay valves can accommodate a maximum air pressure of 150 PSI and maximum hydraulic pressure of 2,000 PSI. The valves can be adjusted to operate at anywhere from a 3:1 to 21:1 hydraulic-to-air-pressure ratio. Maximum operating temperature for the valves is 250 degrees Fahrenheit. MICO, Incorporated designs, manufactures and markets brake systems, hydraulic components and controls, primarily for off-road markets. For more information, contact MICO, Incorporated, 1911 Lee Boulevard, North Mankato, MN 56003, call 507-625-6426, fax 507-625-3212, send an e-mail to micomail@mico.com or visit the company’s website at www.mico.com. |

|

|

|

|

COMPACT,

MOBILE HYDROSWAGE HEAT EXCHANGER TUBE EXPANSION SYSTEM COMPACT,